Our Categories

PRODUCT FAMILIES

KF Moulding has been a trusted manufacturer and supplier of Precast Concrete Steel Moulds for over 30 years of experience, providing practical solutions to challenging problems during the mould design stage. Our innovative technology and durable moulds have been used for a vast range of applications, enabling the speedy and efficient production of high-quality precast concrete elements for our clients.

To ensure the stability and precision of the concrete elements, all our moulds are 3D CAD designed and computer simulated before fabrication. Our product range includes a wide variety of moulds for precast elements such as Break Water Concrete Blocks, Flood and Sea Defense Barriers, New Jersey and Other Road and Security Barriers, Retaining Walls, Fencing, Boundary and Fire Walls, Tanks, Manholes, Channels for Drainage, Custom Culverts, Culvert Headwalls, Cabin & Pods, Vertical Battery wall moulds for Insulated Sandwich Panels, Foundation Plinths and Poles, Tunnel Elements, Columns, Lintels, Beams, Roof Beams, Purlins, Foundation Plinths, Pre-Stressed self-reacting girder moulds, Pre-Stressed Structural Beams, Staircases, Stadium Steps, Elevator Shafts and Bathroom Units, Electrical Cabins, Substation Cells, Cabin and Pods.

At KF Moulding, we are committed to providing our customers with high-quality precast concrete moulds that meet and exceed their expectations.

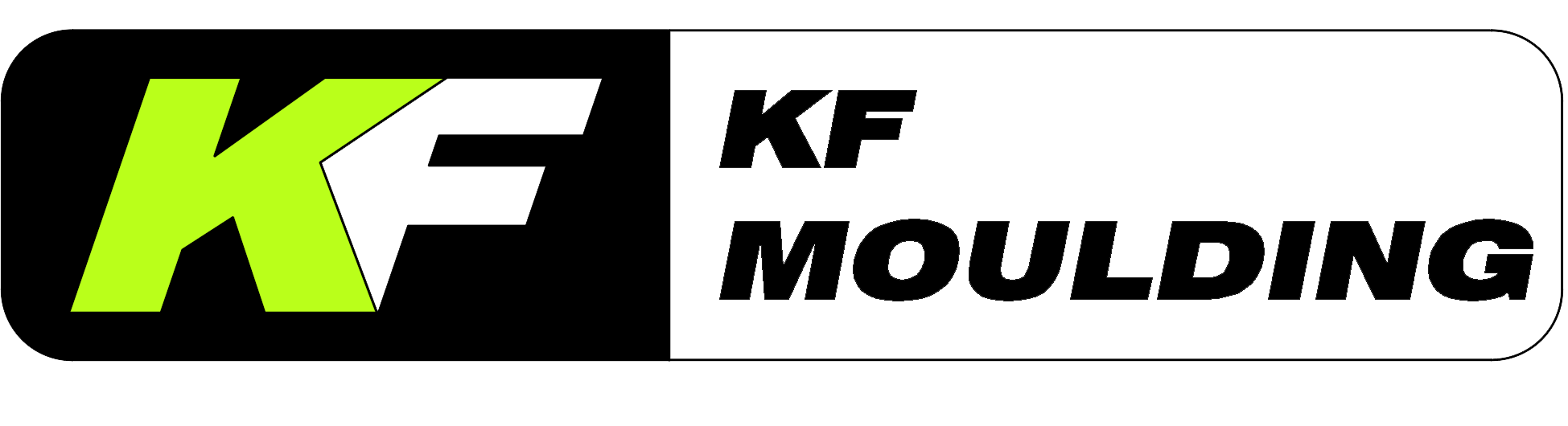

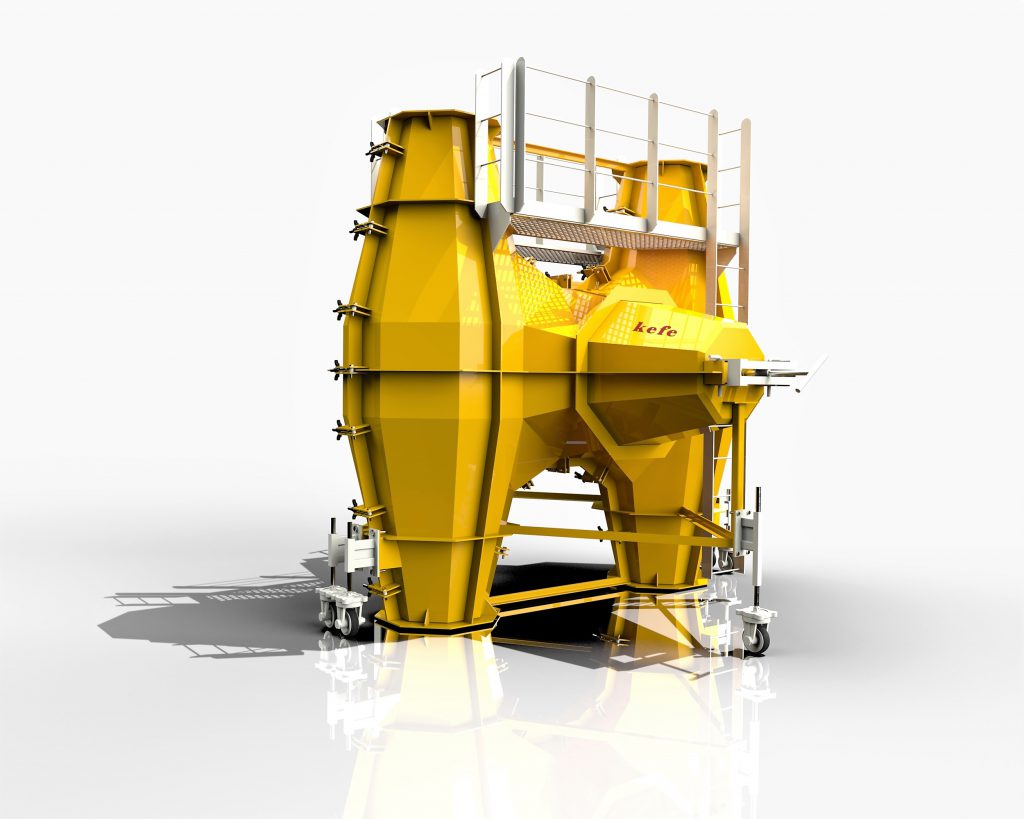

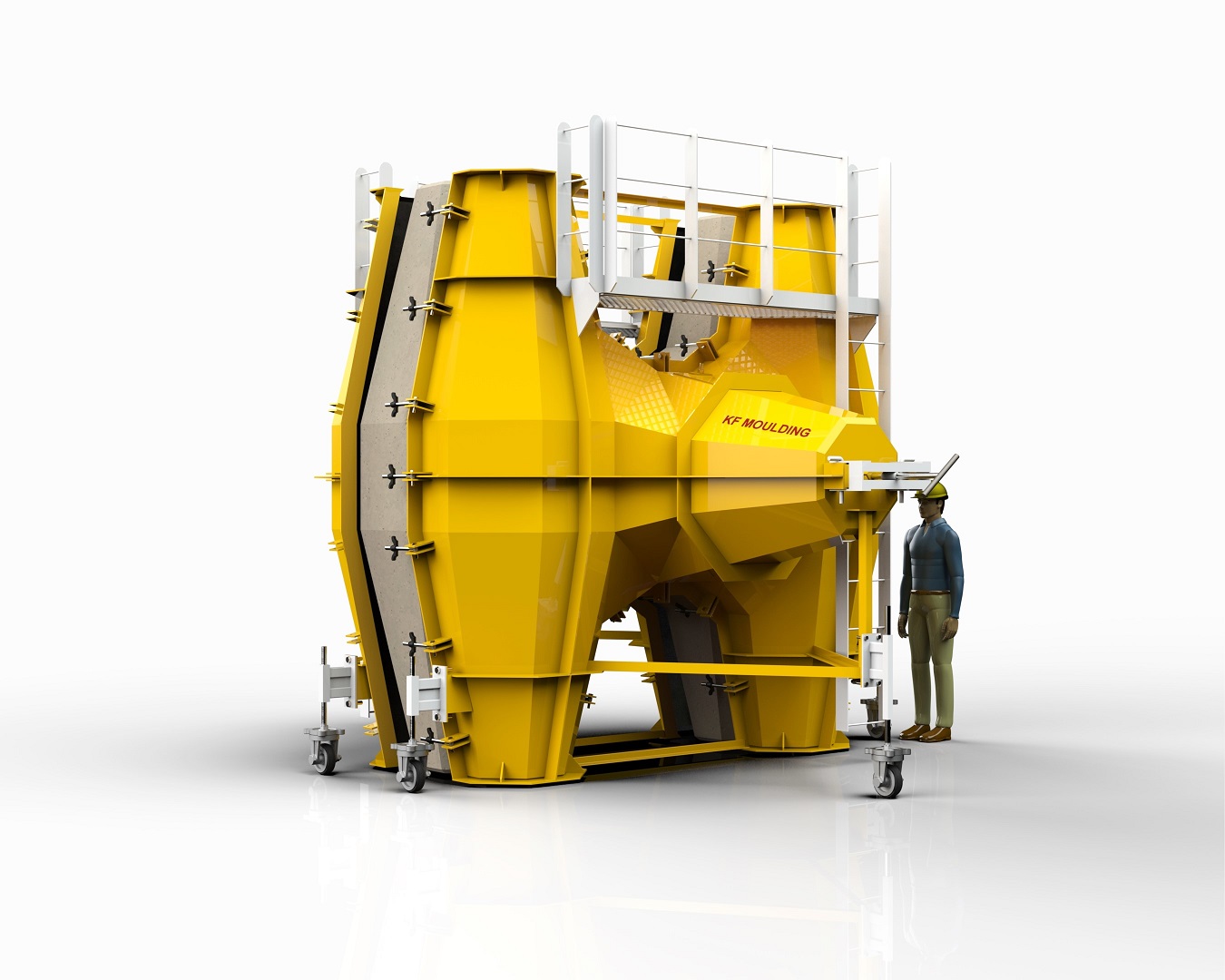

TETRAPOD MOULDS

We have been designing, manufacturing and assembling moulds for Precast Concrete Tetrapods weighing from 1 to 42 tons according to our client's Project requirements. Tetrapods are used as amour units (concrete breakwater units) for protection of exposed coastal structures. Due to the necessity to produce thousands of precast items, durable and long-life Tetrapod Moulds are required ensuring their reusability hundreds of times in the course of the Project Cycle. Through our experience of fabrication of modular formworks, we use steel elements of proper thickness in our moulds.

We determine the optimal production method basing on the latest technologies to fabricate the components in compliance with the European Standards delivering the Project on time. Different than Accropode and Xbloc moulds, Tetrapod moulds have a bottom segment (part) and a cast concrete block needs to be kept in the mould until it gets cured.

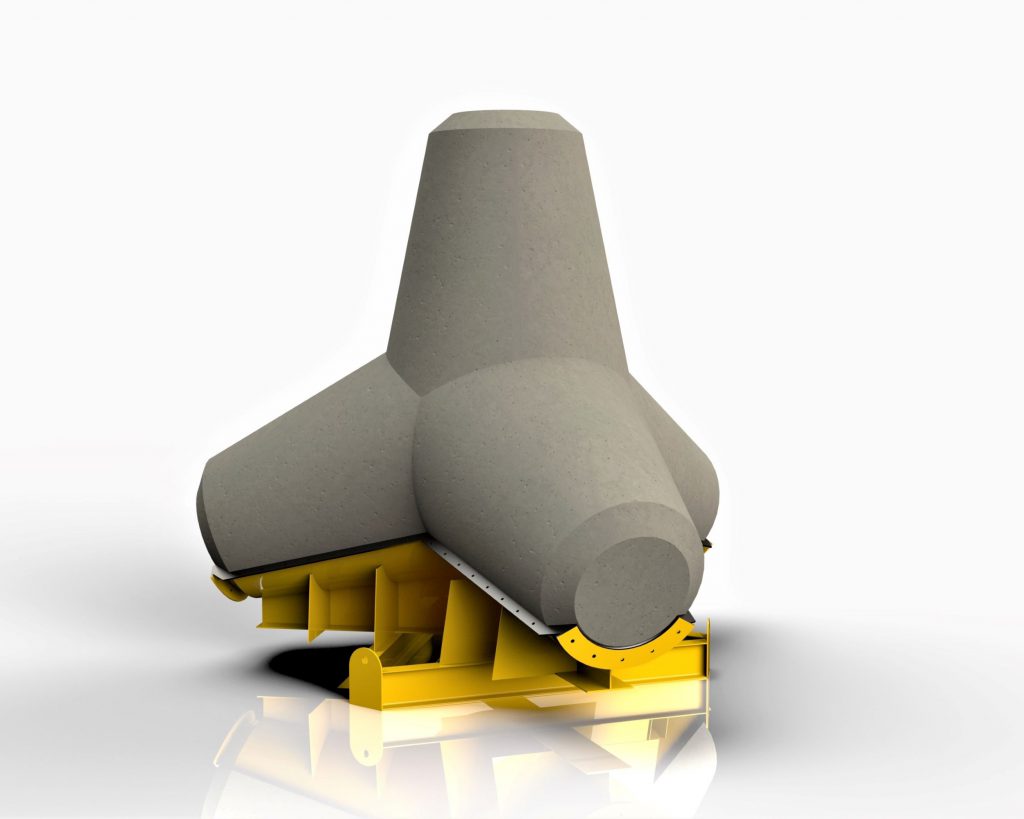

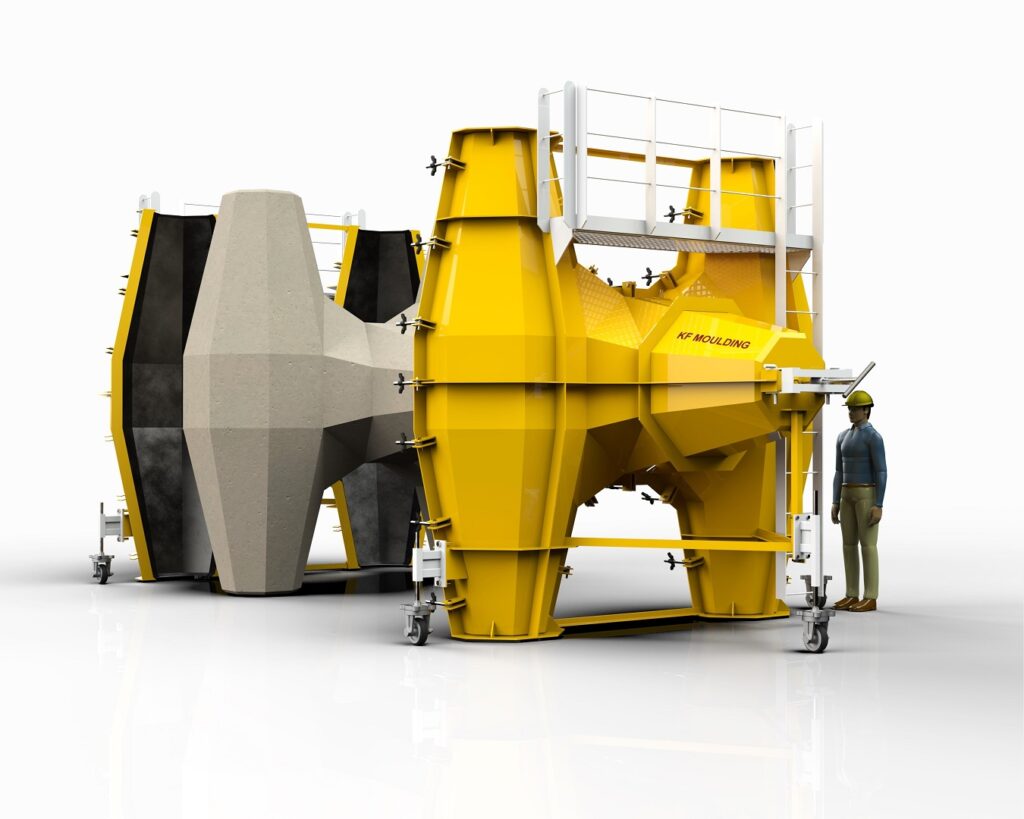

Xbloc® MOULDS

We produce high-quality moulds for Precast Concrete Xblocs from 1 to 20 cubic meters in accordance with Your Time-Schedule. We determine the optimal production method basing on the latest technologies to fabricate the components in compliance with the European Standards delivering the Project on time.

Xbloc® technology designed and developed by DMC (Delta Marine Consultants) / BAM

Xblocs are used as Armour units (concrete breakwater units) for protection of exposed coastal structures. Due to the necessity to produce thousands of precast items, durable and long-life Xbloc Moulds / Formworks are required ensuring their re-usability hundreds of times in the course of the Project Cycle. Through our experience of fabrication of modular formworks, we use steel elements of proper thickness in our moulds.

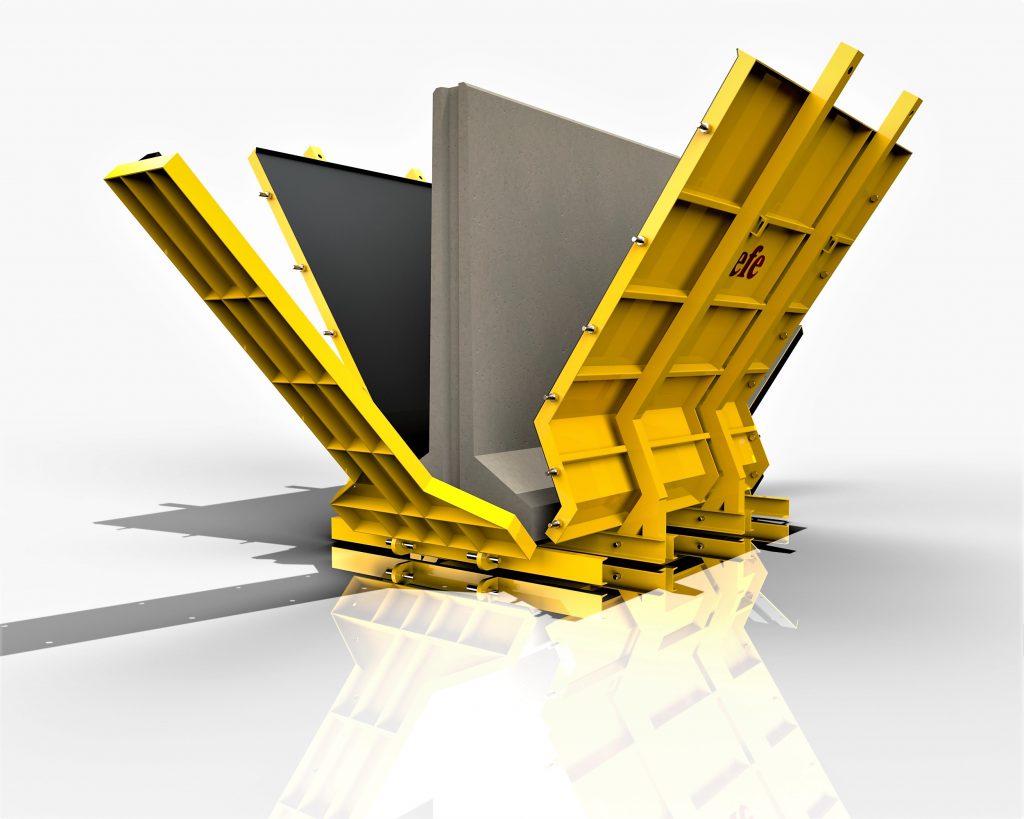

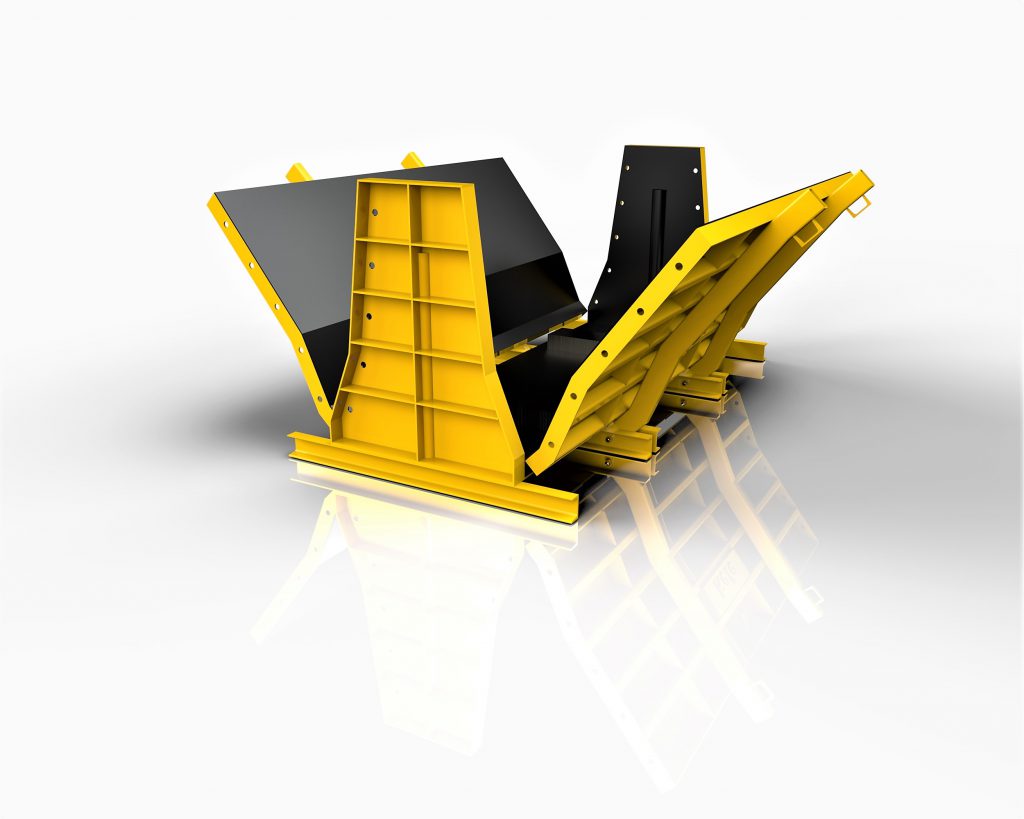

ACCROPODE™ ii MOULDS

The ACCROPODE™ II formwork consists of two symmetrical, bottomless half-shells that can be separated. They are assembled to create a mould into which the concrete is poured. The two half-shells are separated by being struck using a jack that presses on the end of the noses. We produce moulds for Precast Concrete Accropodes from 1 to 20 cubic meters and we produce custom sizes according to project requirements of our clients .

ARTELIA Eau & Environnement as Licensor has granted an exclusive licence to CLI (Concrete Layer Innovations) to represent the proprietary ACCROPODE™ II technology.

Accropodes are used as Armour units (concrete breakwater units) for protection of exposed coastal structures. Due to the necessity to produce thousands of precast items, durable and long-life Accropode Moulds / Formworks are required ensuring their re-usability hundreds of times in the course of the Project Cycle. Through our experience of fabrication of modular formworks, we use steel elements of proper thickness in our moulds. Accropode Moulds over 5 m³ are produced out of 4 parts for easier transportation.

Accropode™ MOULDS

The ACCROPODE™ formwork consists of two symmetrical, bottomless half-shells that can be separated. They are assembled to create a mould into which the concrete is poured. The two half-shells are struck using a jack that presses on the end of the noses, thus detaching the form from the ACCROPODE™ block.

Through our experience of fabrication of modular formworks, we use steel elements of proper thickness in our moulds. Accropode Moulds over 5 m³ are produced out of 4 parts for easier transportation.

ARTELIA Eau & Environnement as Licensor has granted an exclusive licence to CLI (Concrete Layer Innovations) to represent the proprietary ACCROPODE™ technology.

CORE-LOC™ MOULDS

The CORE-LOC™ formwork consists of two symmetrical, bottomless half-shells that can be separated. They are assembled to create a mould into which the concrete is poured. The two half-shells are struck using a jack that presses on the end of the noses, thus detaching the form from the CORE-LOC™ block. The dimensions of CORE-LOC™ blocks vary from 1 to 11 cubic meters. Any intermediate dimensions are also available for the production based on the project needs.

ARTELIA Eau & Environnement as Licensor has granted an exclusive licence to CLI (Concrete Layer Innovations) to represent the proprietary CORE-LOC™ technology.

Core-Locs' are used as Armour units (concrete breakwater units) for protection of exposed coastal structures. Due to the necessity to produce thousands of precast items, durable and long-life Core-Loc Cycle. Through our experience of fabrication of modular formworks, we use steel elements of proper thickness in our molds.

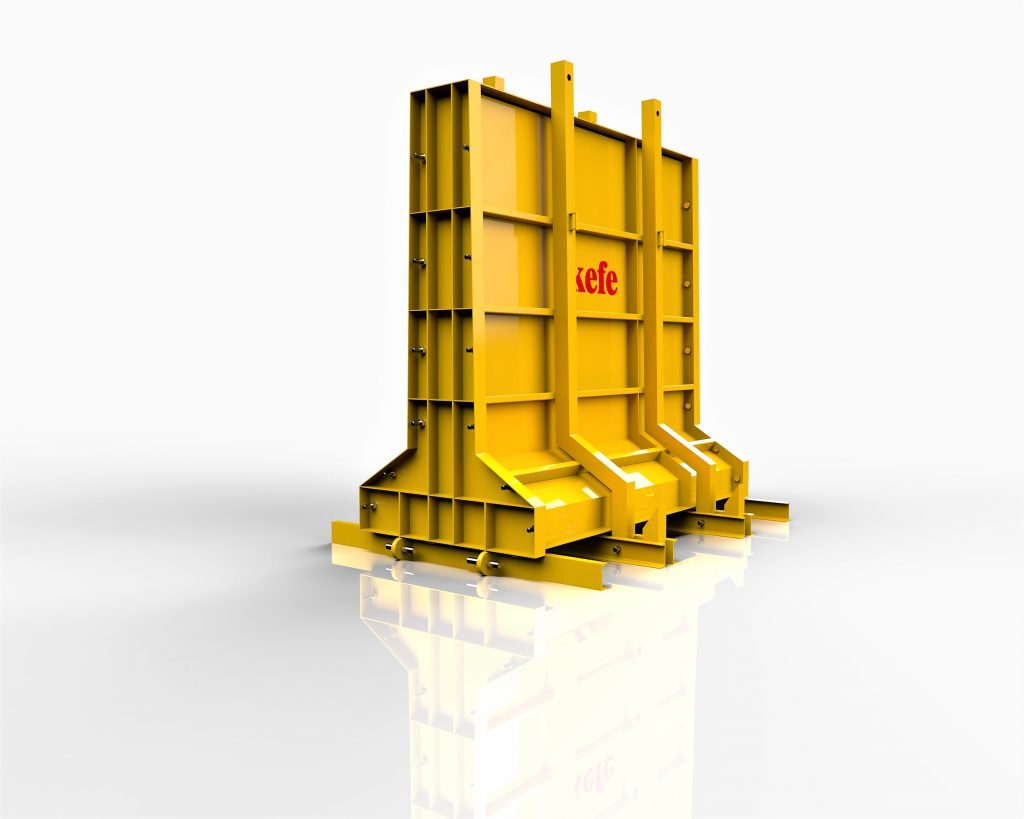

T-WALL BARRIER MOULDS

KF Moulding manufactures Steel Barrier Moulds for various precast elements. Our T-Wall Moulds provide solutions for Your customized needs such as interlock design systems to form unity of multiple elements and Forklift transportation to Your Project Locations.

T-Walls are mainly used for security purposes. Their installation creates safe zones on military bases and restricted areas.

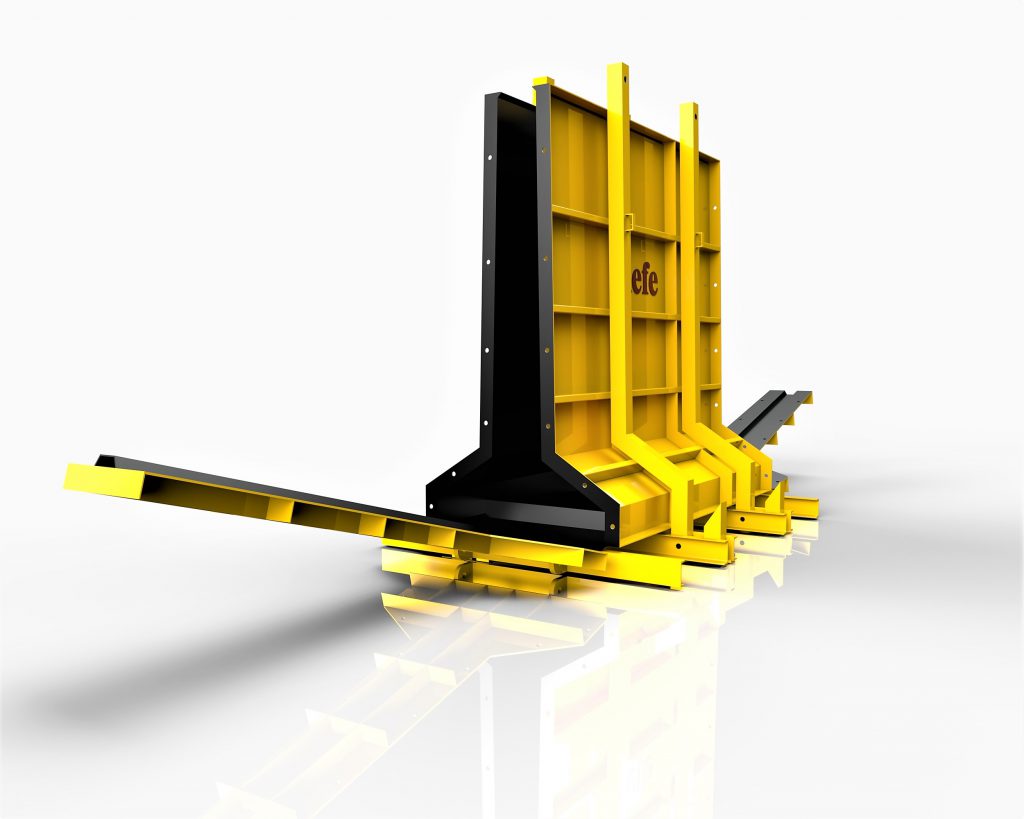

JERSEY BARRIER MOULDS

KF moulding manufactures Steel Barrier Moulds for various precast elements. Our New Jersey Barrier Moulds provide solutions for Your customized needs such as interlock design systems to form unity of multiple elements and Forklift transportation to Your Project Locations.

New Jersey Barrier are mainly used to separate the traffic lanes. It is designed to minimize vehicle damage in case of incidental contact.

ALASKA BARRIER MOULDS

Alaska Barrier are mainly used for security purposes. Their installation create safe zones on military bases and restricted areas.

Alaska Barriers have standard dimensions. In some areas there are requirements to have higher walls. For the walls above 3 meters KF Moulding have different solutions to provide safe de-moulding.

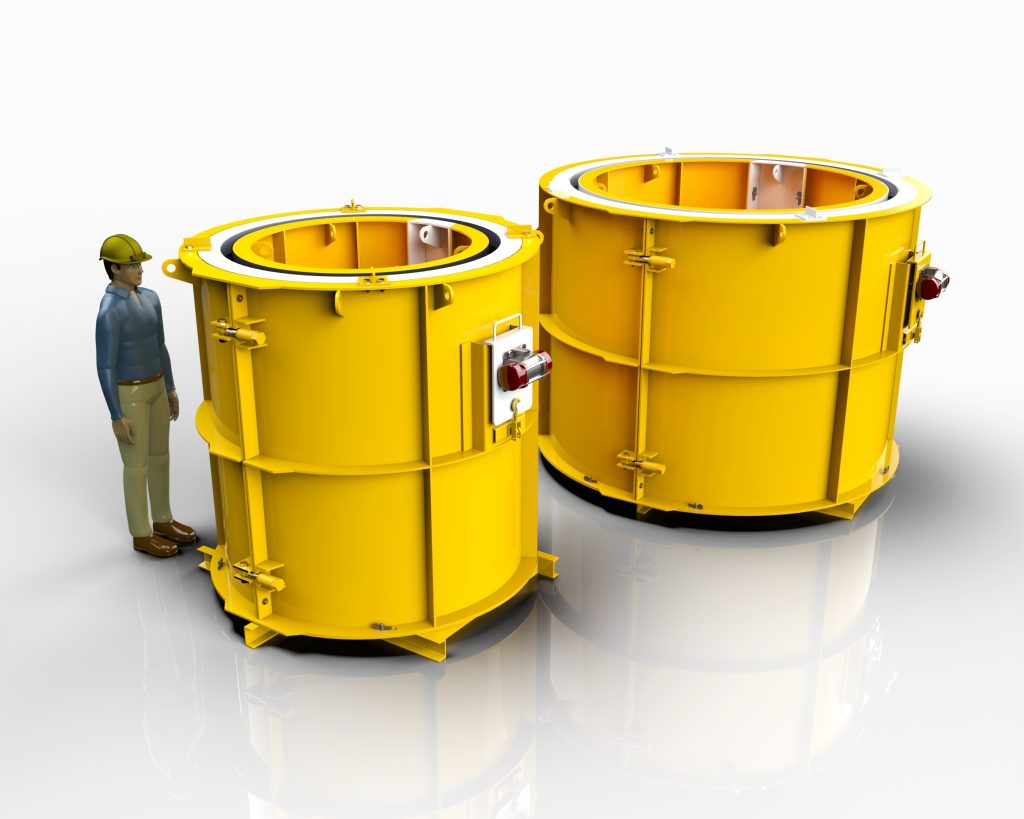

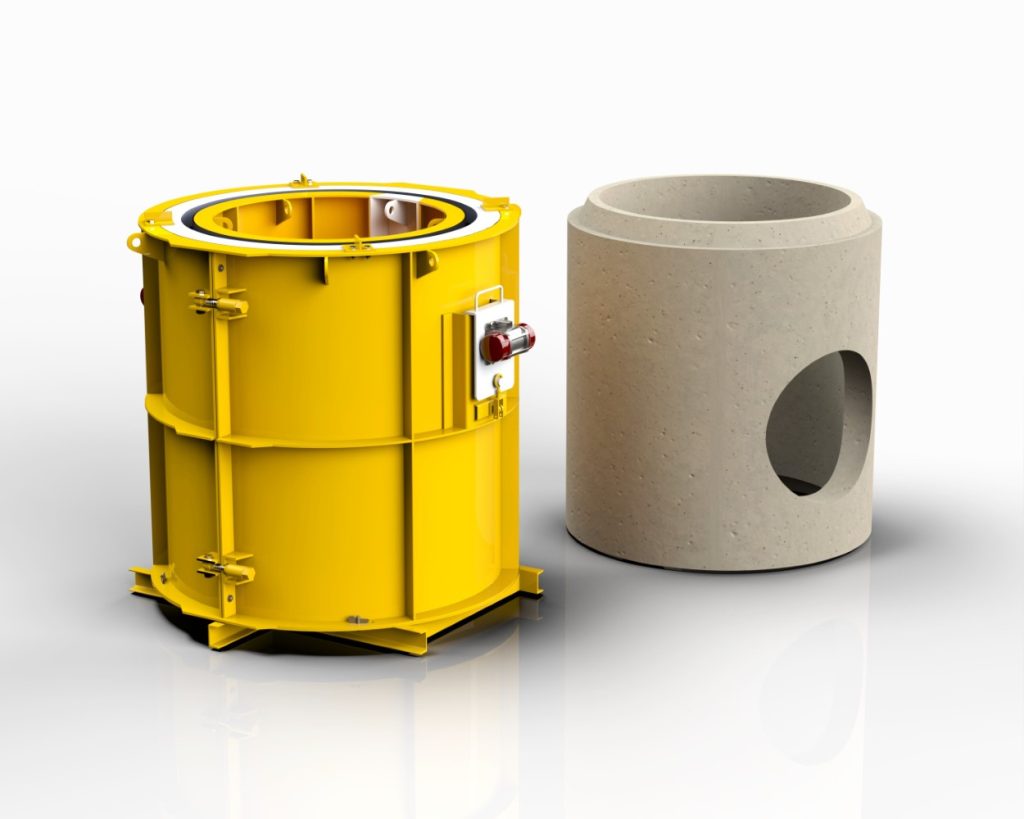

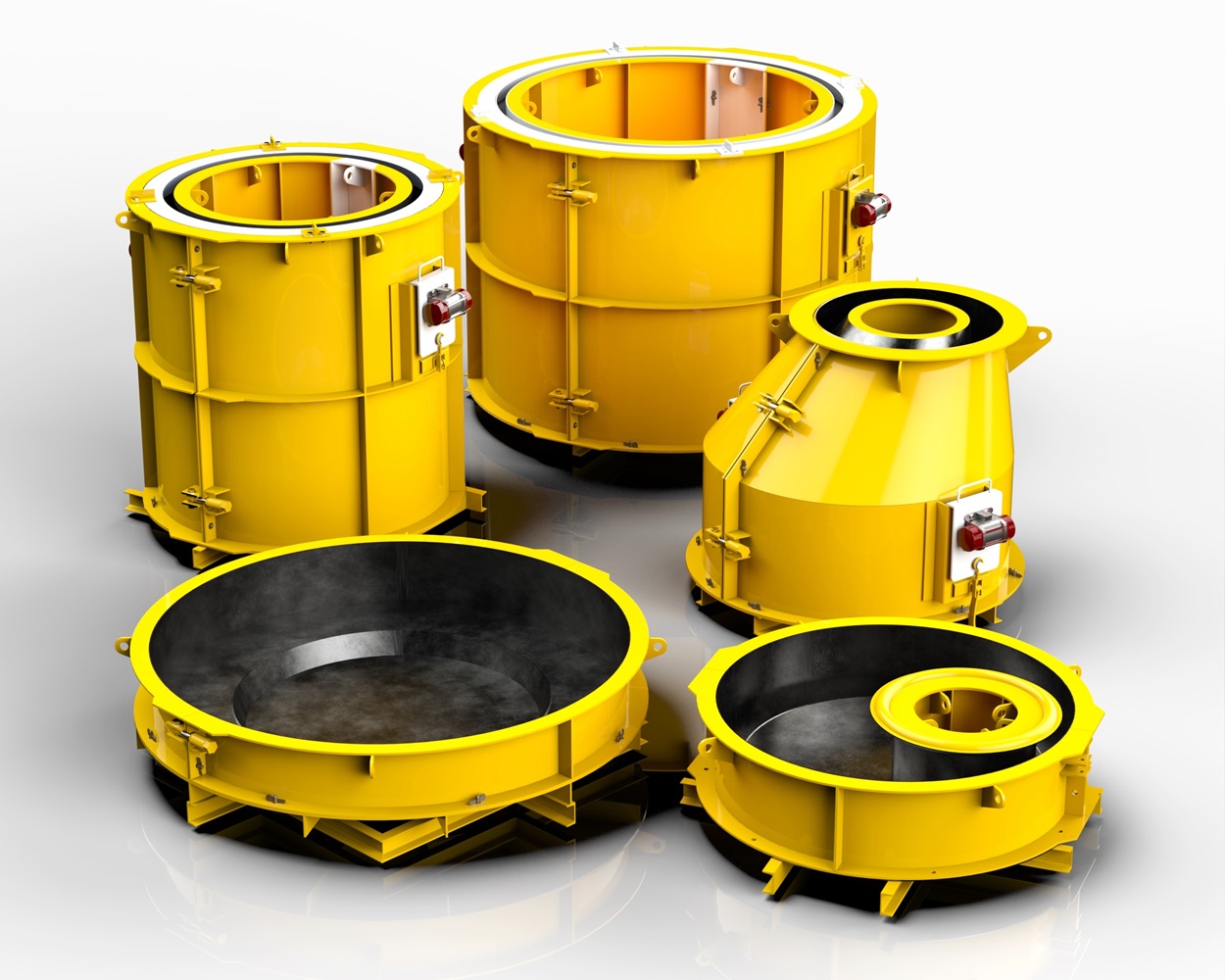

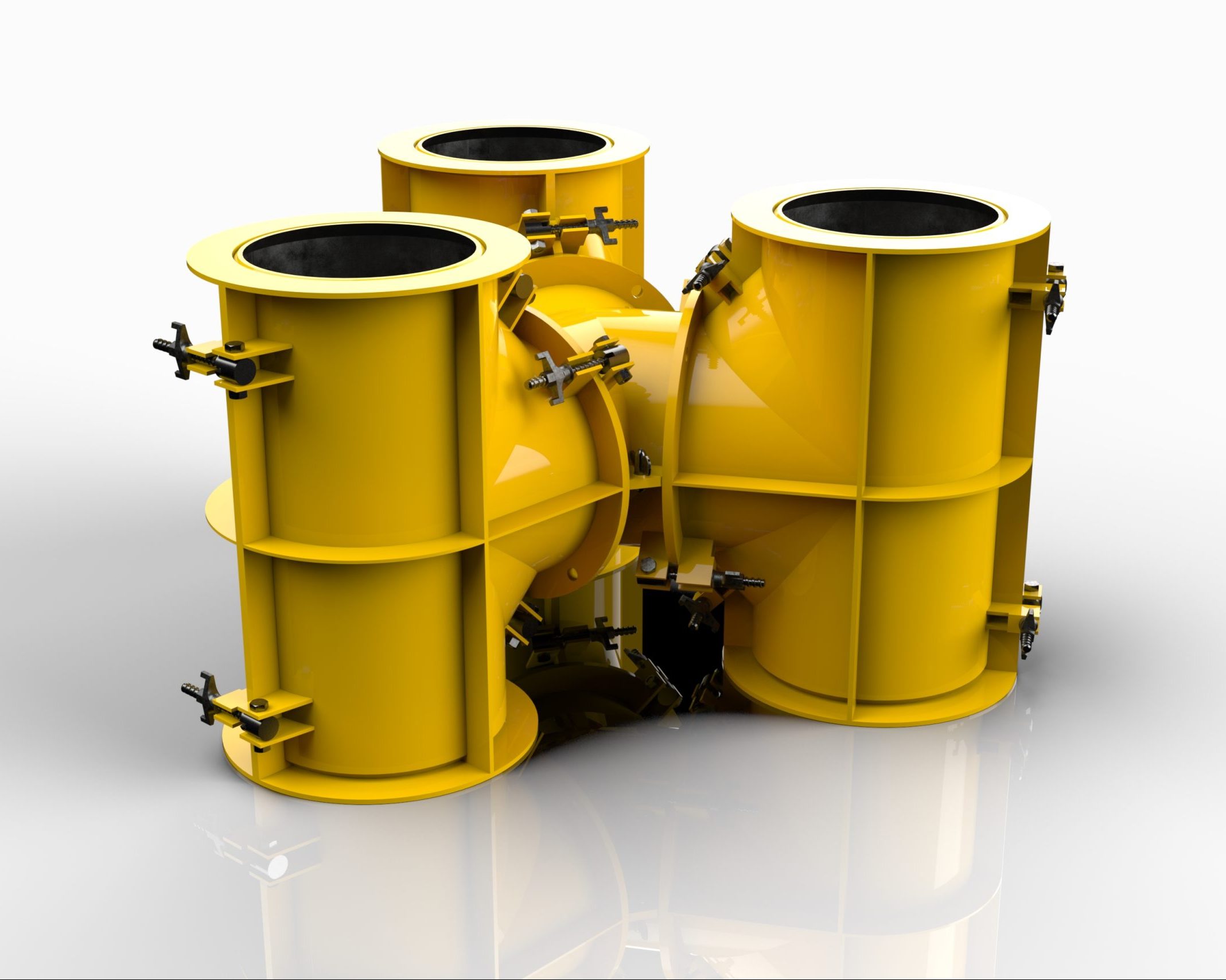

MANHOLE MOULDS

Manhole molds are a pivotal component within the construction industry, providing essential support for creating sturdy and long-lasting manholes. The molds consist of several segments, such as the Base Slab Forms, Riser Forms, Top Slab Forms, and Eccentric Cone Forms, each contributing to the optimal functioning and structure of the manhole. It's worth noting that the Riser mold is equipped with a unique adjustable Tongue form that enables the production of varying height elements, adapting to the specific requirements of each construction site.

Utilizing these molds provides construction teams with the ability to reach necessary manhole heights, guaranteeing an efficient and precise project outcome. The durability and longevity of manholes created using these molds underlines their importance within the construction process.

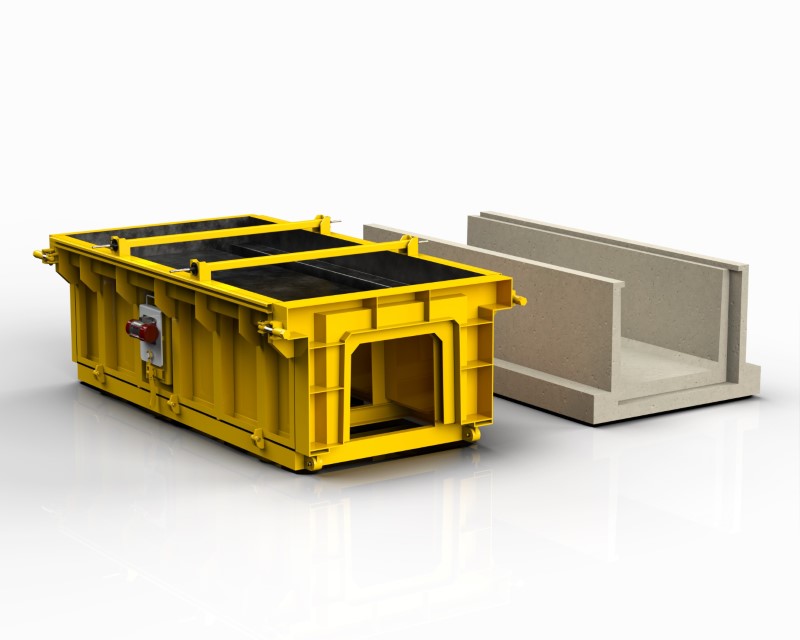

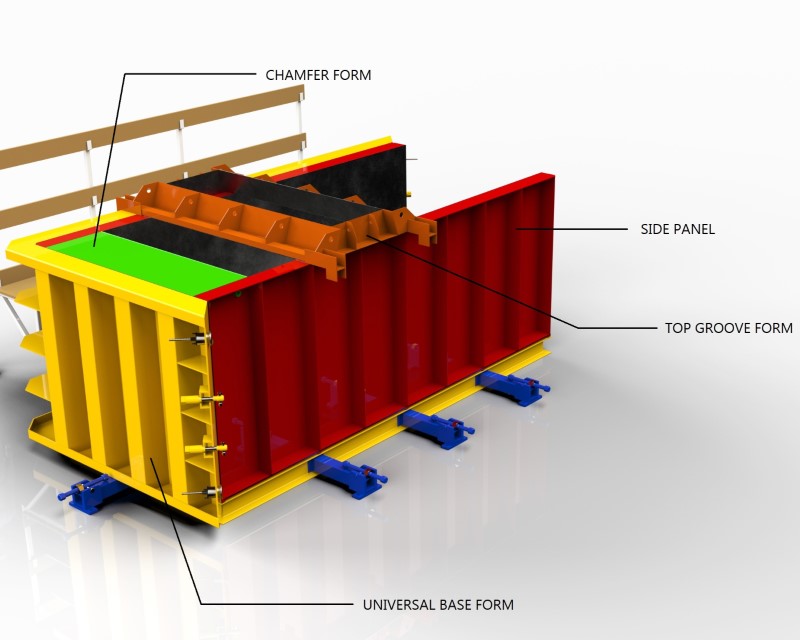

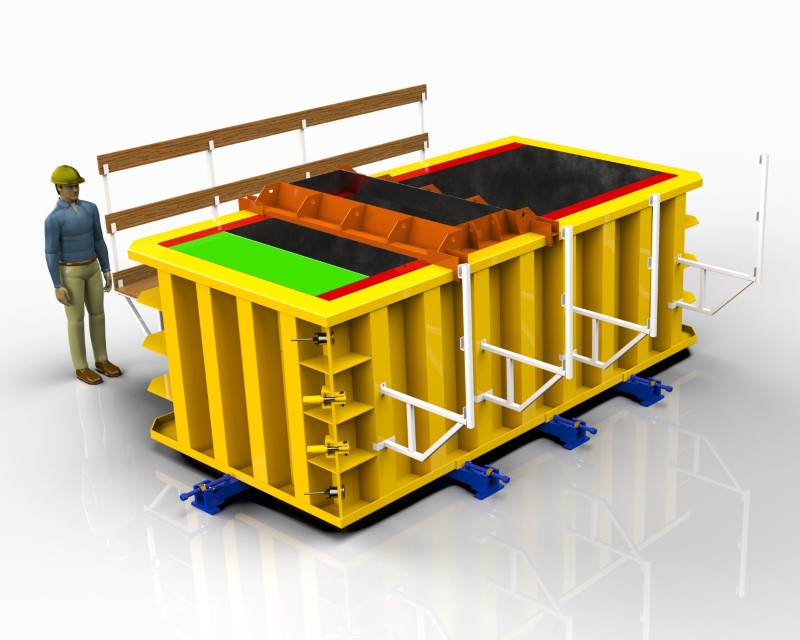

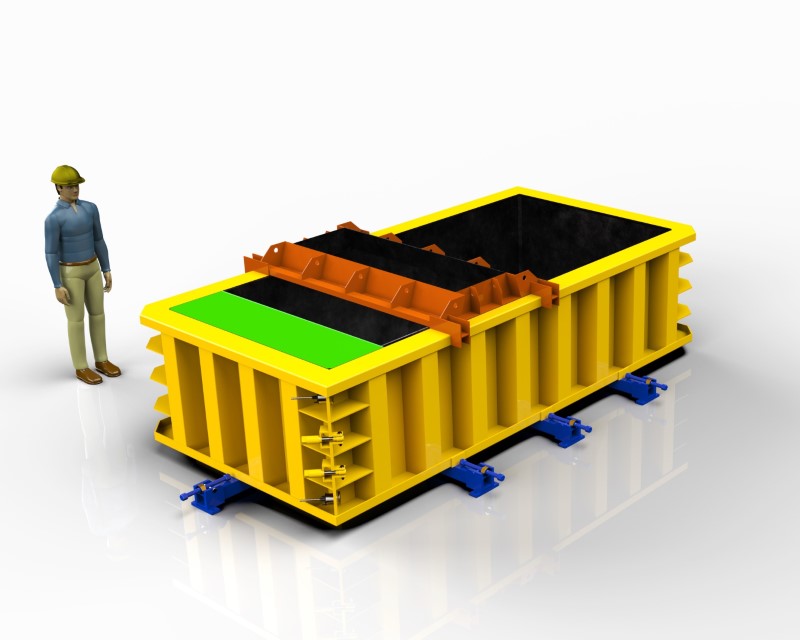

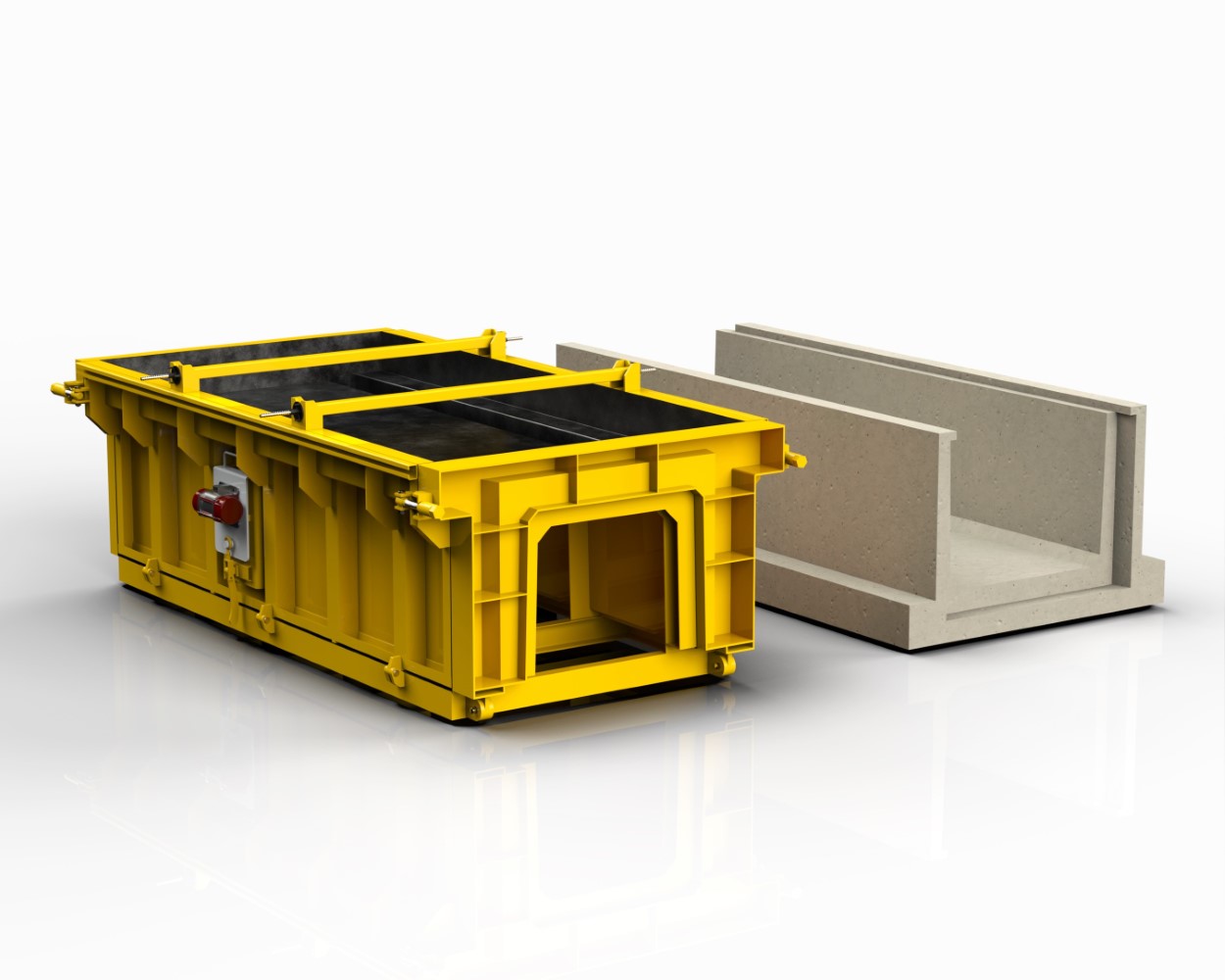

DITCH-CHANNEL MOULDS

KF Moulding manufactures custom Ditch-Drain molds tailored to clients' project specifications concerning dimensions and sizes. These precast elements serve various purposes, including Drainage Channels, Ditches, or Trenches, and are shaped in an inverted U form. The molds feature hinged outer walls, facilitating easy demolding. Ditch molds are available in sizes ranging from 1 meter to 8 meters.

Each mold is equipped with tongue and groove sealing joint details. Separator panels enable the production of customized channel segments of preferred lengths. These optional separator panels are secured and stabilized using magnet shutters positioned at the base surface of the molds.

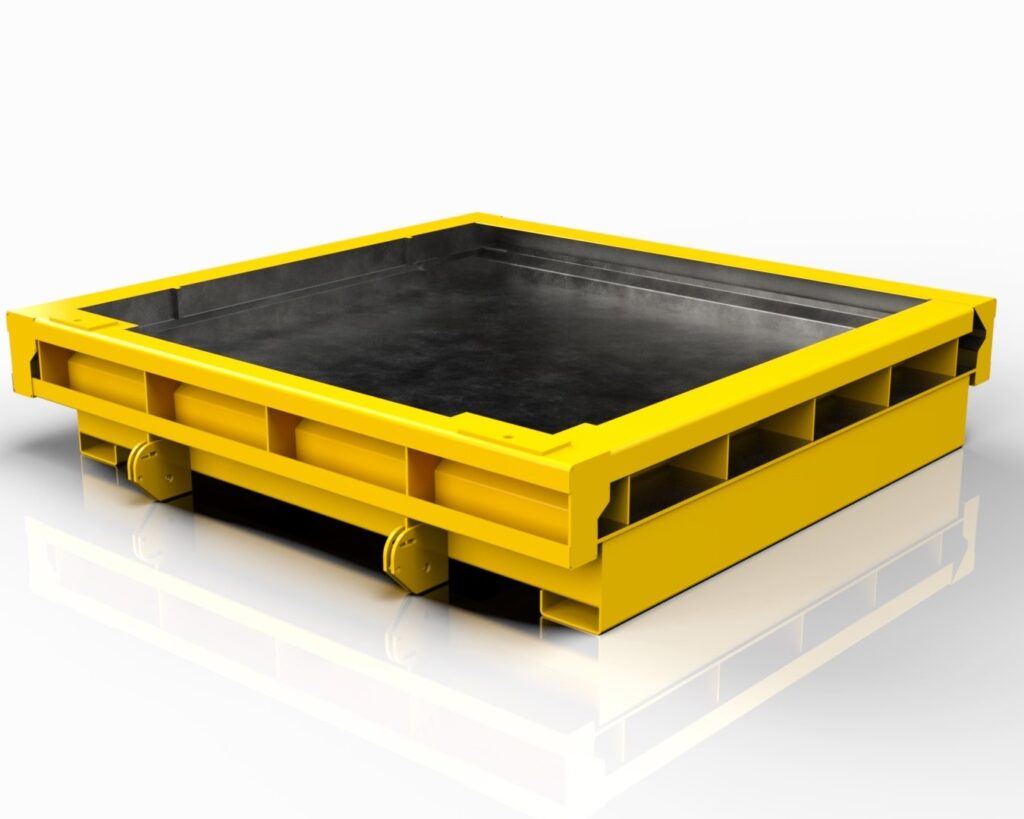

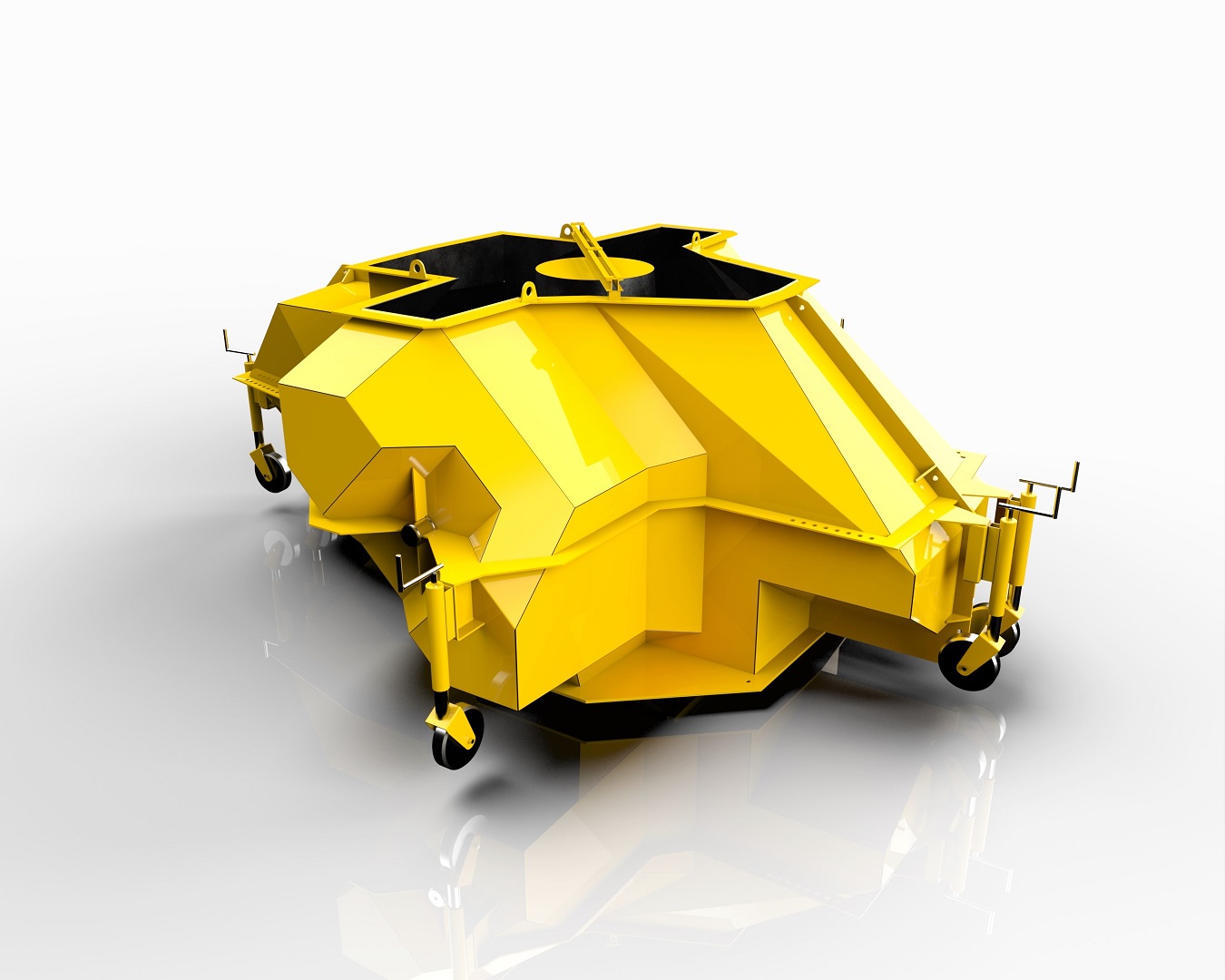

QUAY BLOCK MOULDS

Quay Block Molds enable producers to replicate designs with remarkable accuracy, ensuring reliability in the construction of port infrastructures and marine barriers.

They enhance efficiency and uniformity in production, offering not just a product but a solution that empowers construction projects with durability and resilience, especially as marine projects often demand thousands of blocks. These molds serve as the cornerstone of durable and resilient blocks for Quay wall projects.

CULVERT MOULDS

Molds for precast concrete culverts can be used to create culverts of various shapes and sizes, including circular, elliptical, and box culverts. They can also be used to create culverts with special features, such as wing walls, headwalls, and inlet and outlet structures. We produce expandable and hydraulic version of the moulds for various sizes and dimensions.

We can produce any kind of mould depending upon the requirement of the concrete products by our clients. Some of these moulds are- culvert mould, storm water drain mould, tunnel moulds, coping moulds etc. These moulds are fabricated to produce customised individual elements with varying sizes.

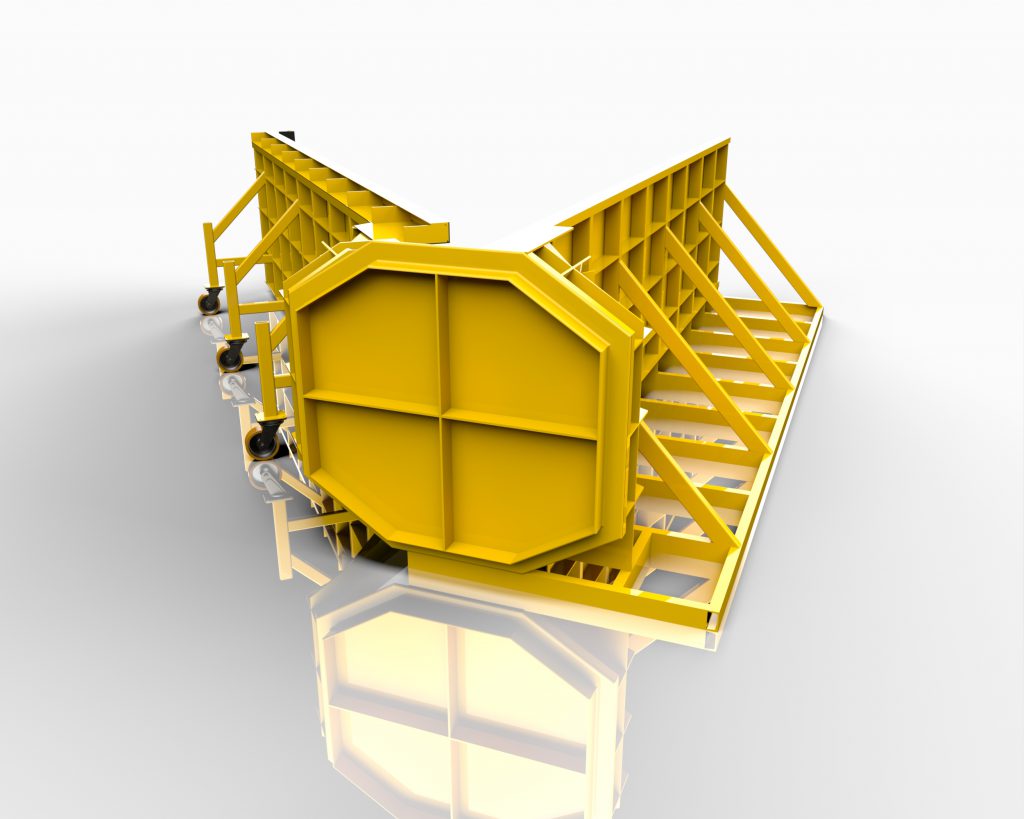

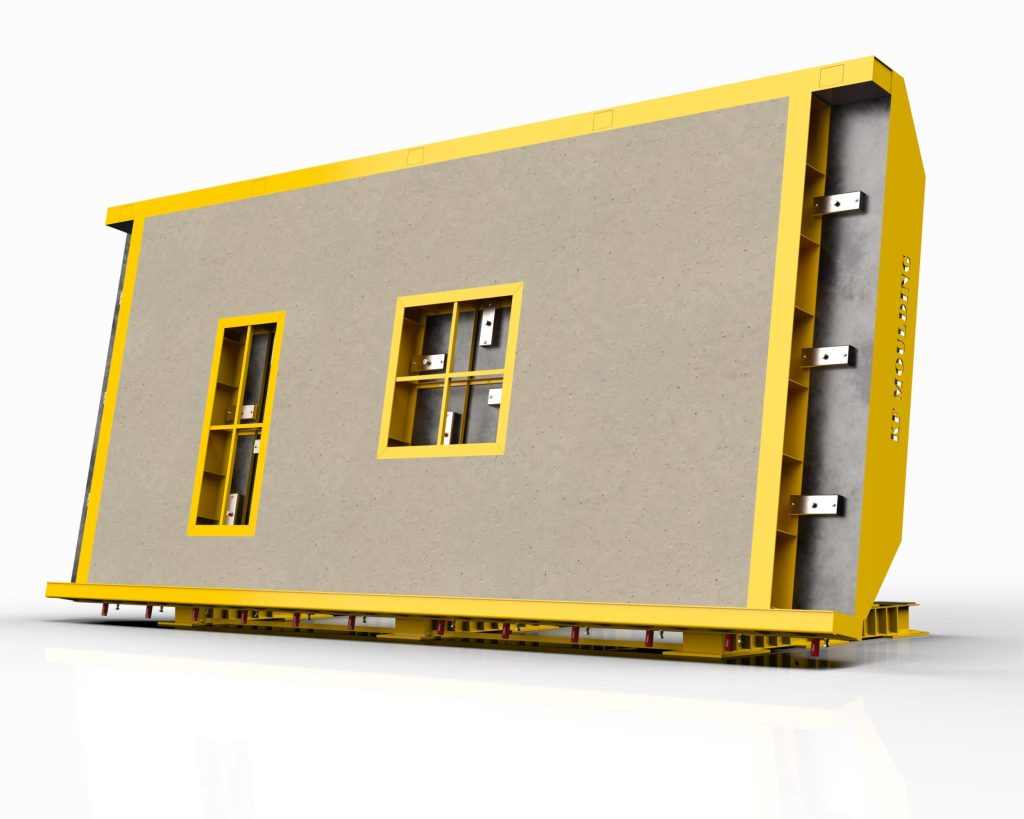

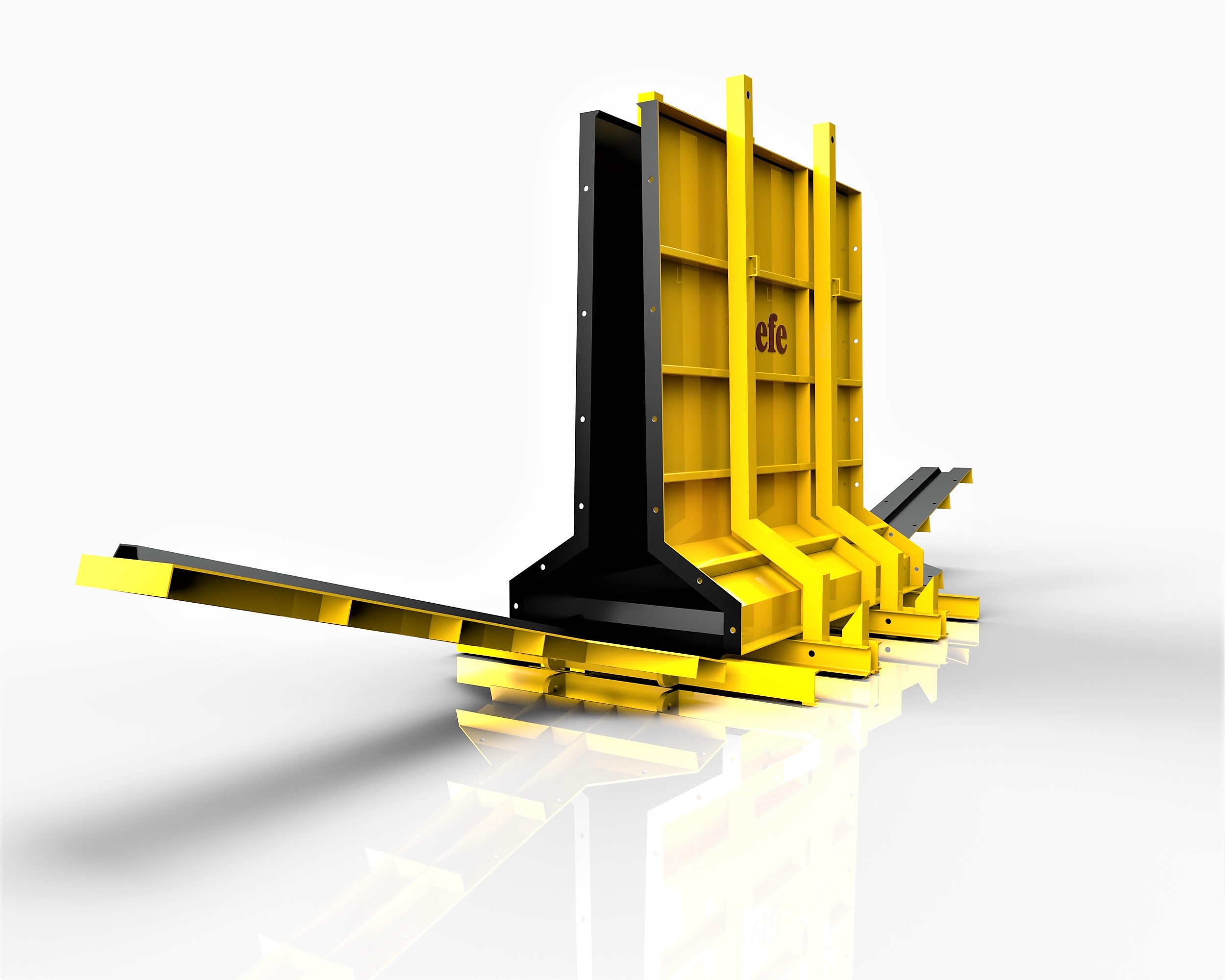

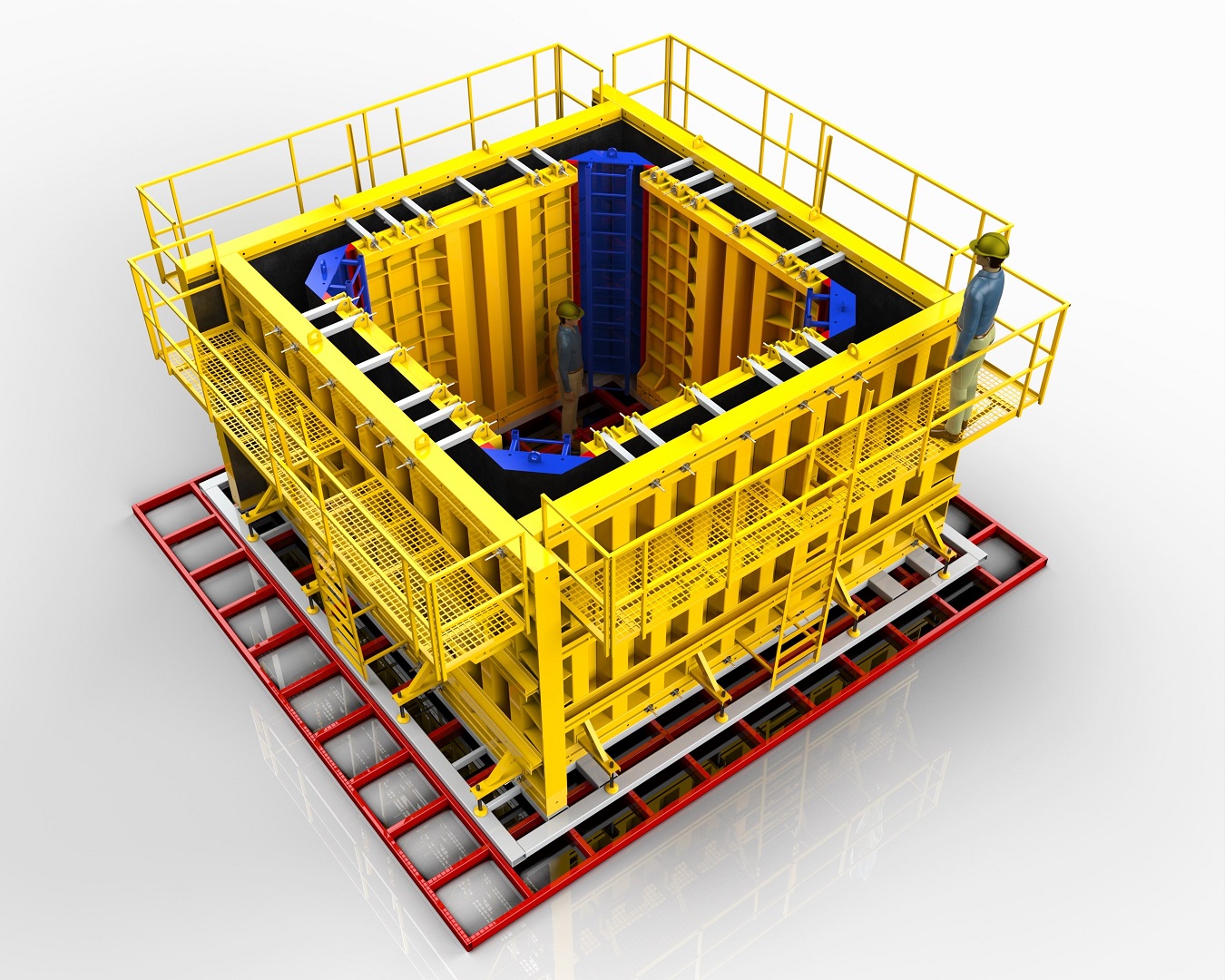

VERTICAL WALL MOULDS

Vertical Panel Wall Moulds allows producers to have customized dimension precast concrete wall panel with preferred finishing on both sides. In addition having the mould vertically standing, it occupies less space for manufacturing and de-moulded easily. Structurally the mould has fixed central frame, side frames move on rails for the preparation and de-moulding of the concrete. The two independently moving side elements have 10mm thick surface plates to ensure the rigidity and not to have deformation in its lifecycle.

The hinged side doors allow to have the concrete product in full extend as well as bottom and side panels with magnets are used to get customized wall width and height. For door and window frames similar panels with shuttering magnet can be placed in accordance with the project. The vibration systems allows the uniform compaction of the concrete. Optionally for fast curing, pipping system carrying hot water can also be installed on the mould face.

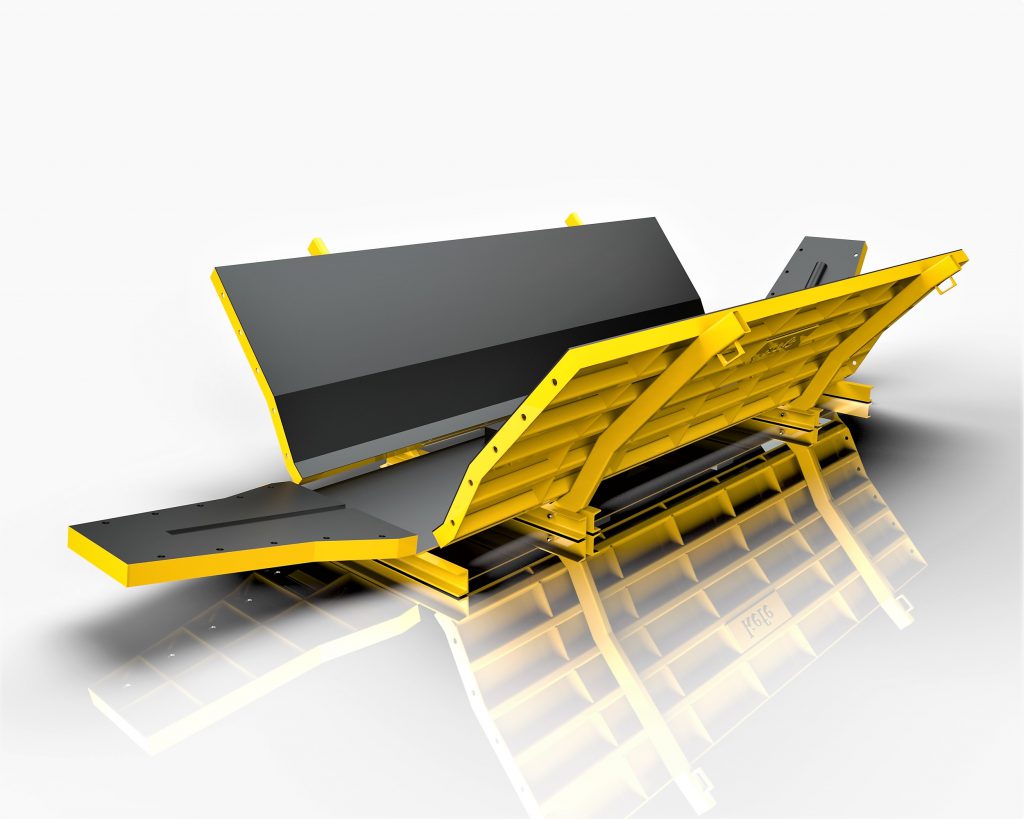

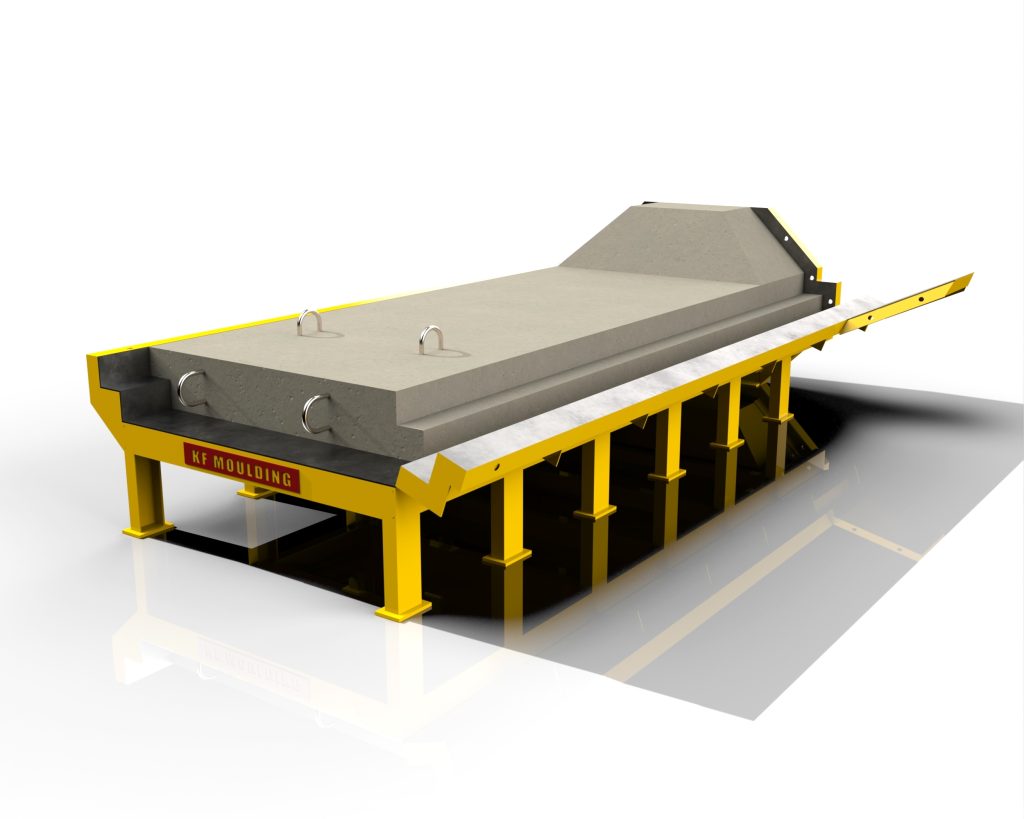

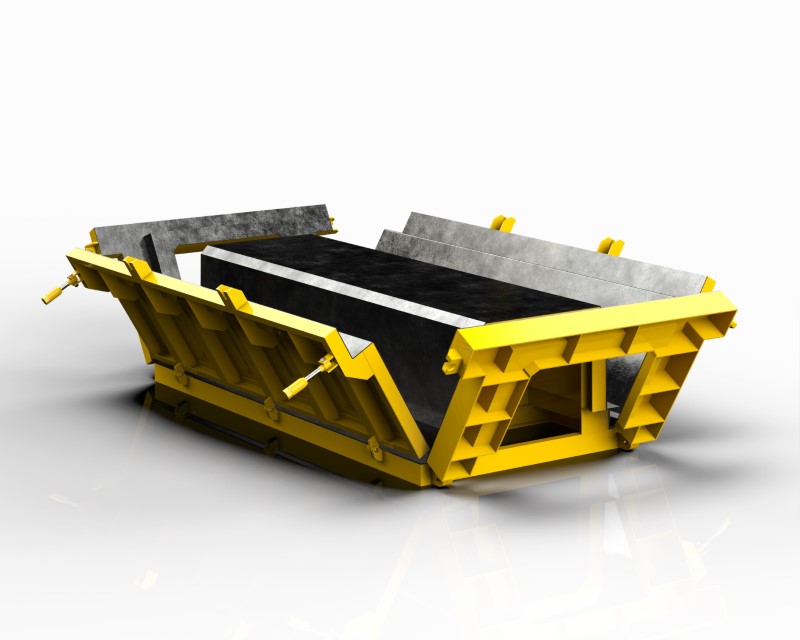

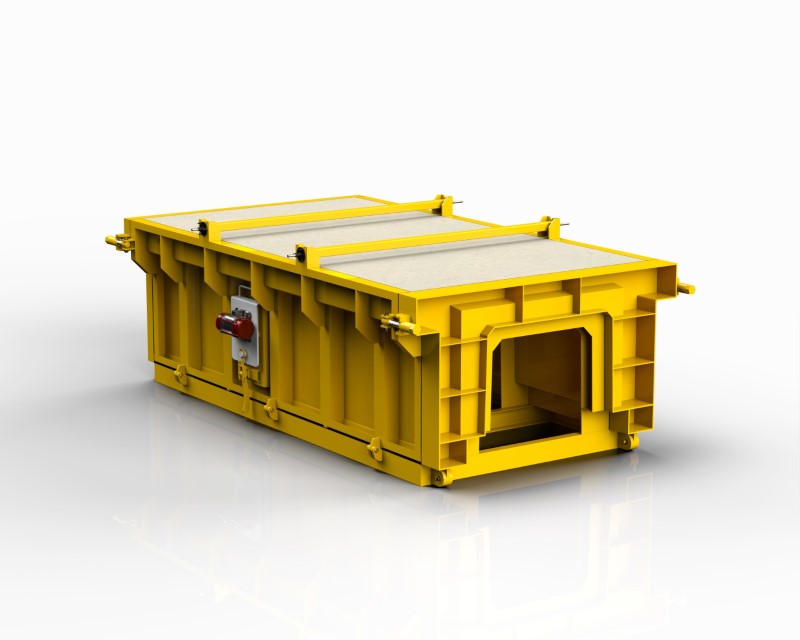

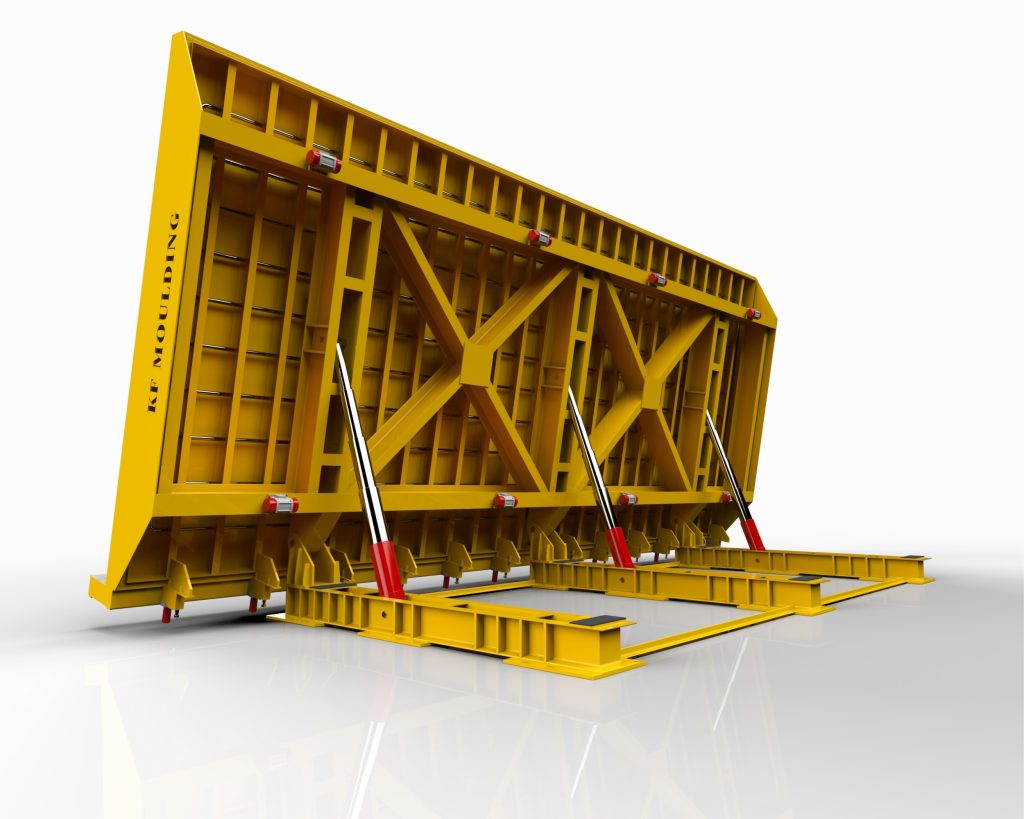

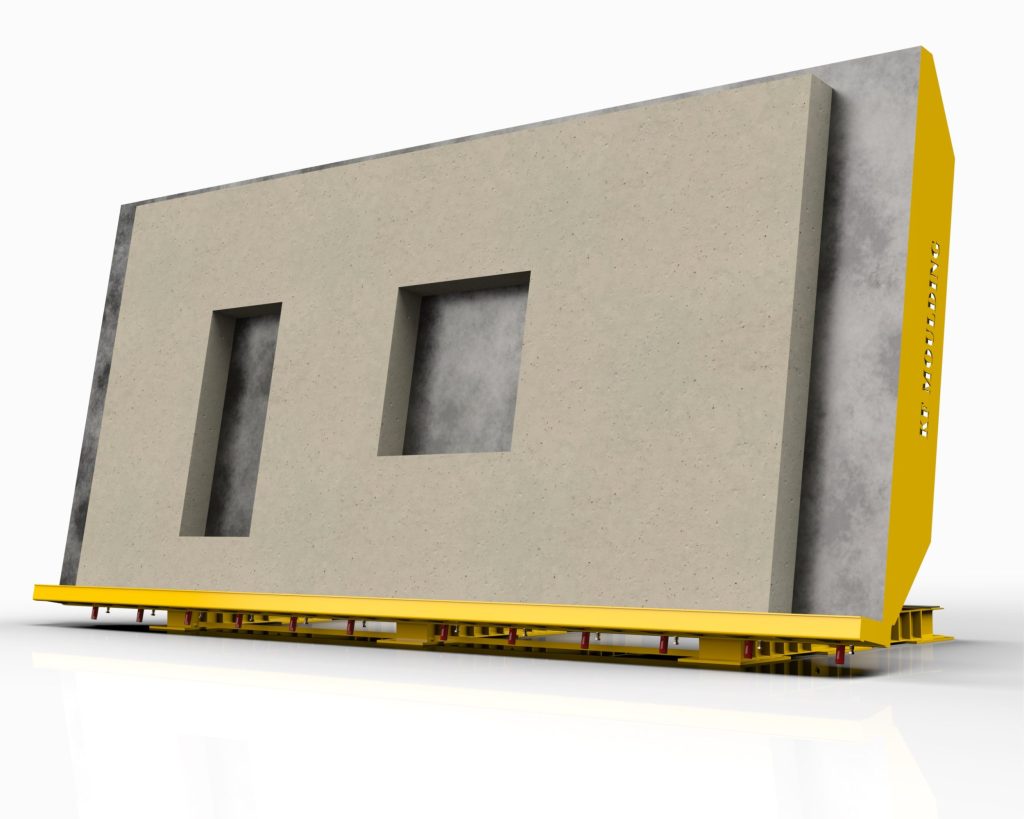

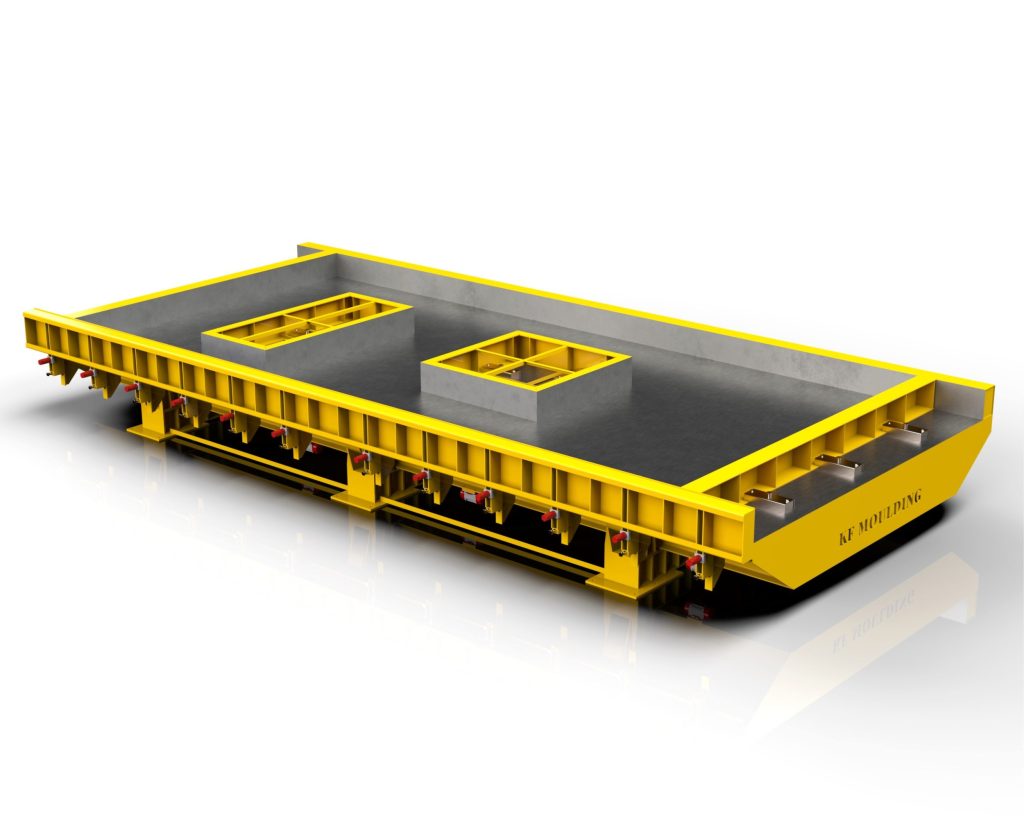

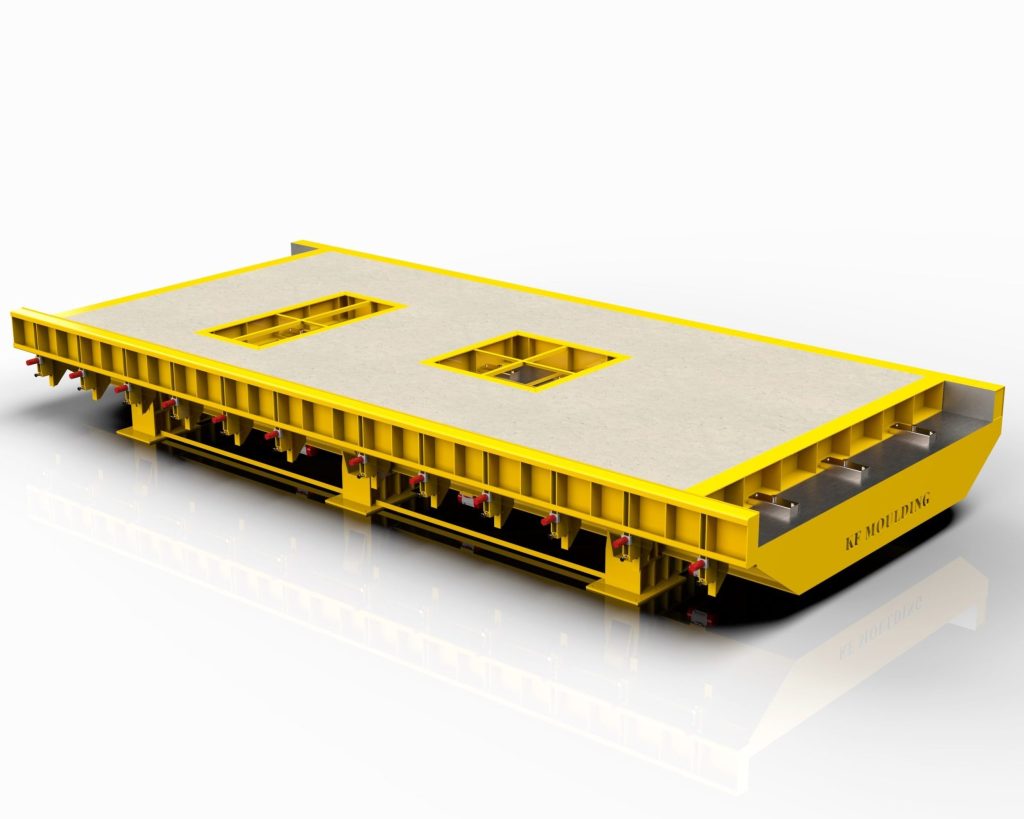

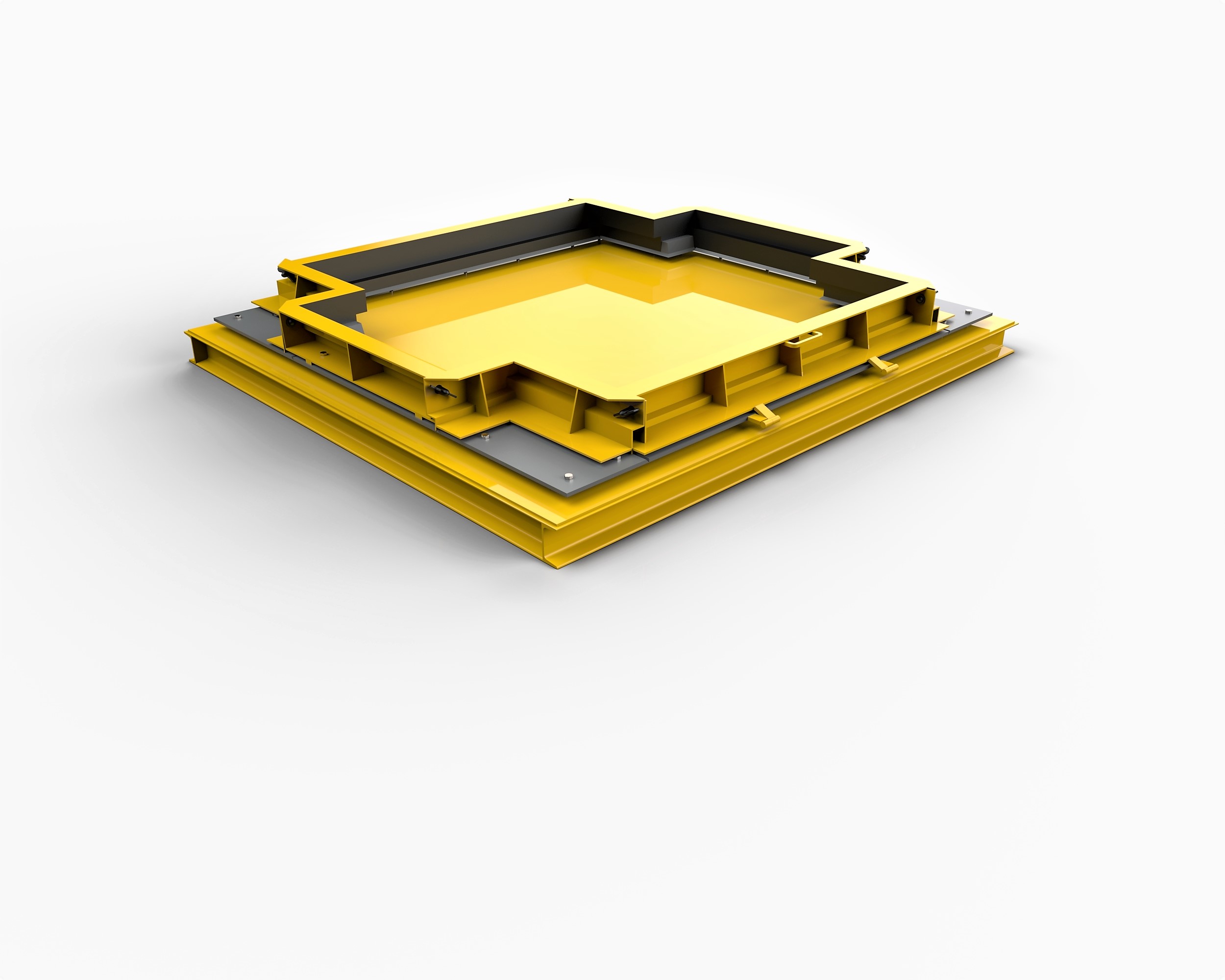

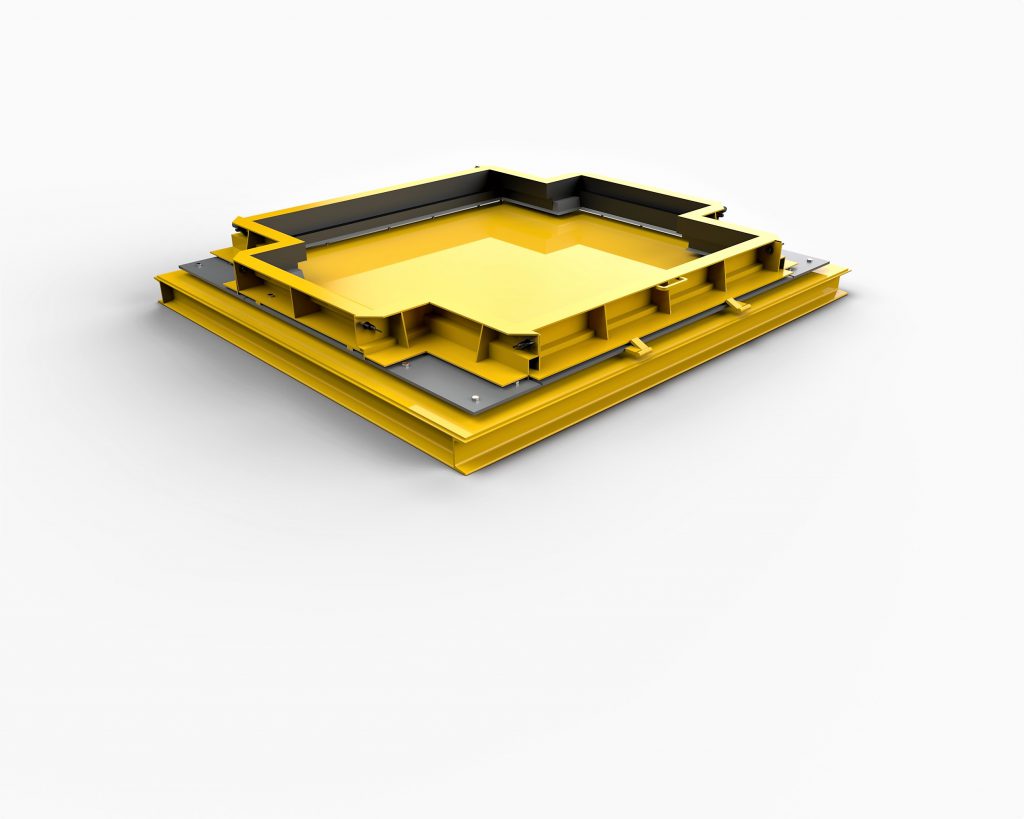

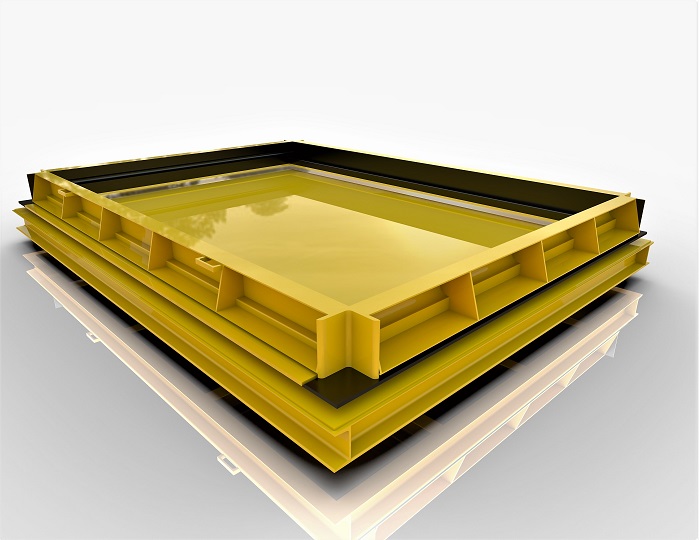

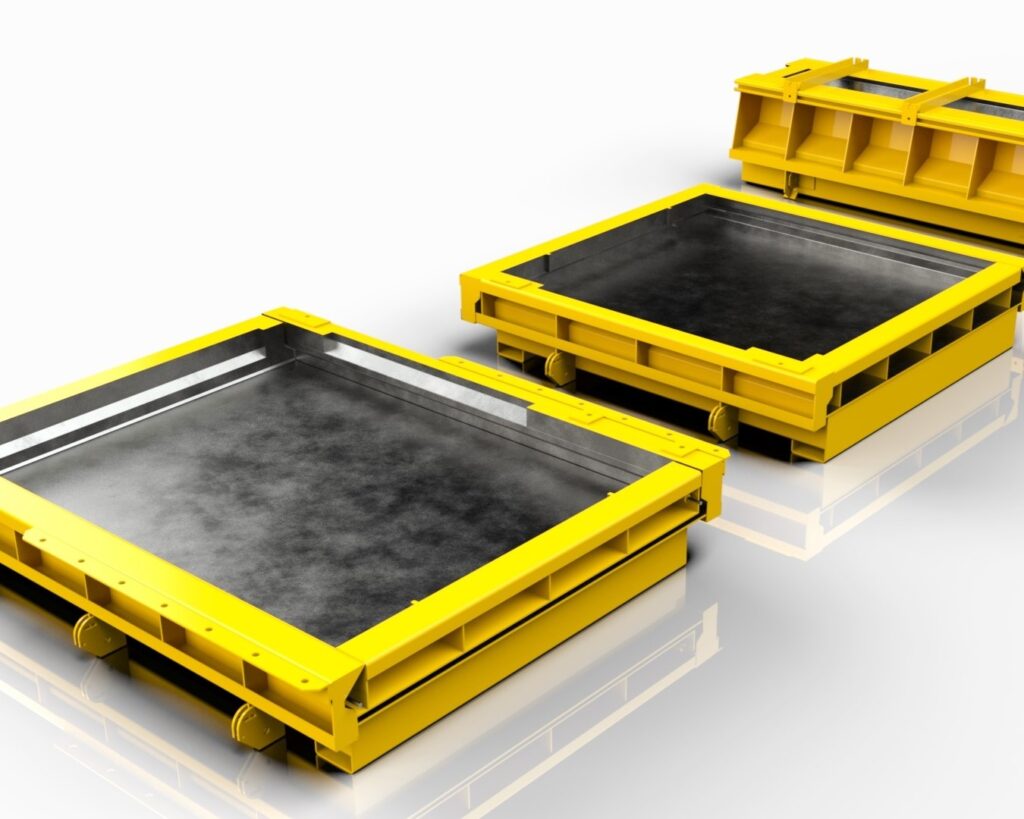

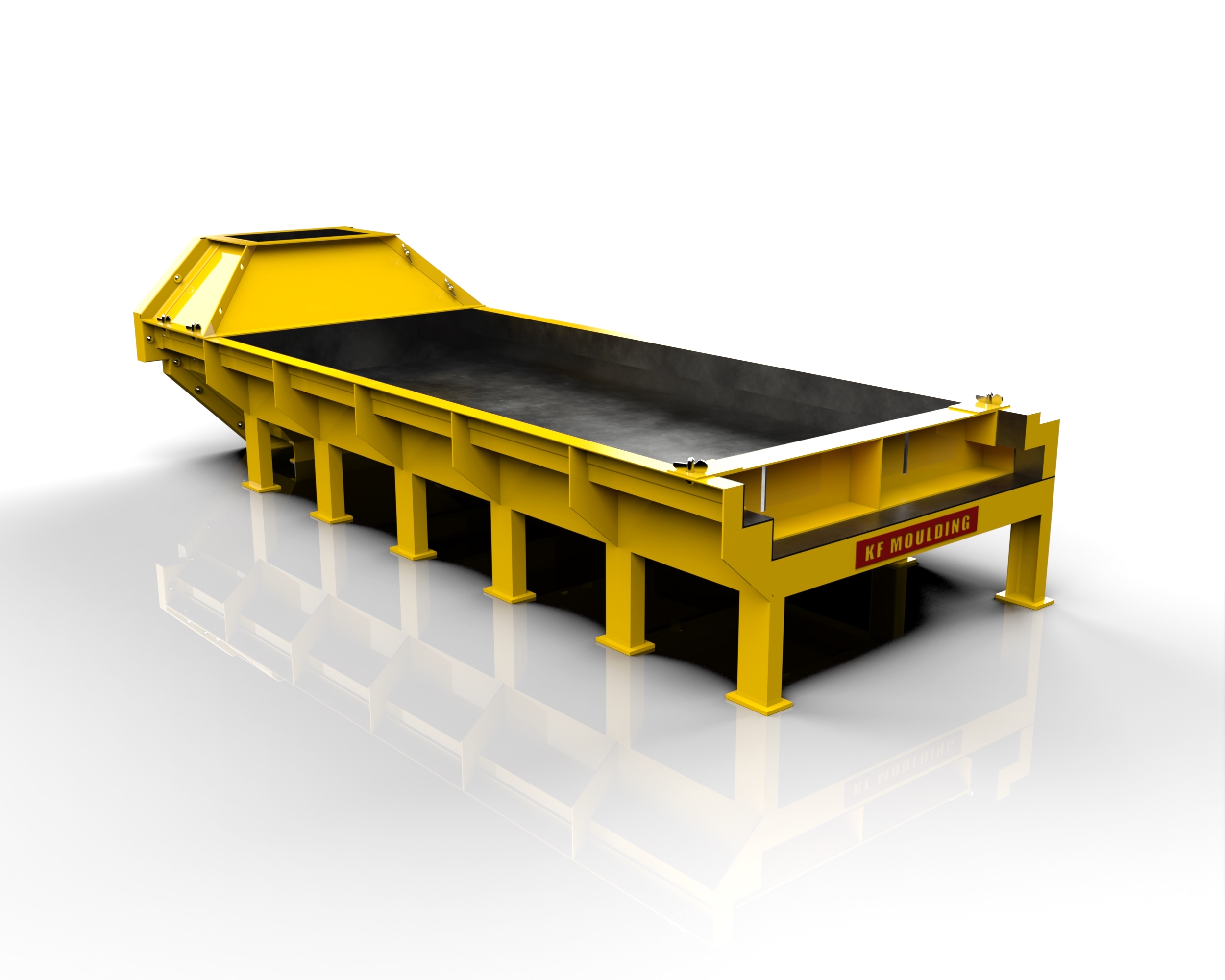

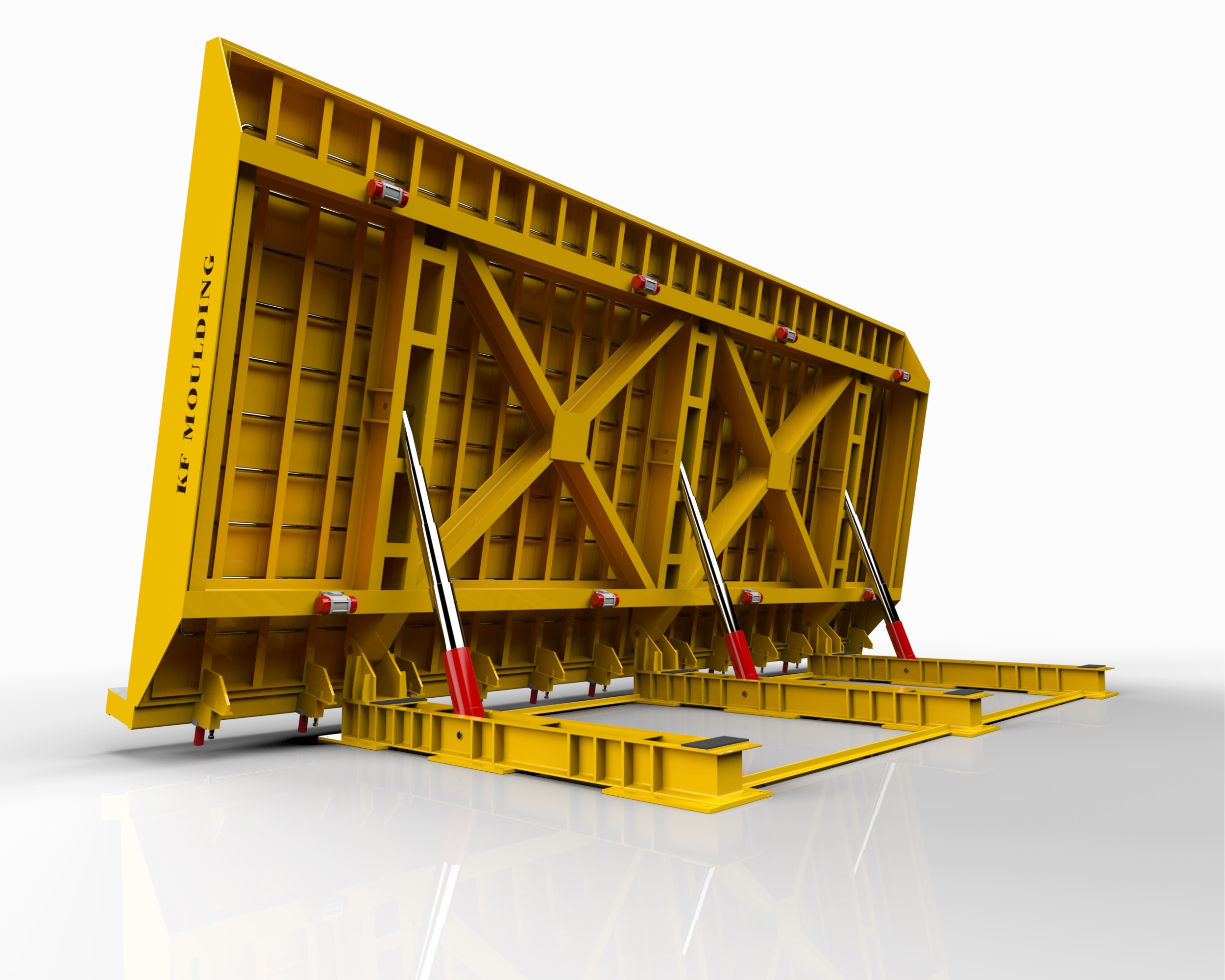

TILTING TABLES

Tilting Tables are used for the production of large precast concrete panel walls in various construction fields such as residential, commercial or industrial. KF Moulding Tilting Tables are designed for the use of wall panels with different thicknesses. The adjustable bottom section of the mould enables produce 100mm to 400mm thick concrete wall panels. The sides panels with shuttering magnet elements allows the production of adjustable wall width and height in accordance with each specific construction design. The Shuttering mechanisms are also used for the door and window frames.

It is also possible to produce sandwich panel wall systems to have decorative finish and having insulation materials installed in the wall structure. The hot water pipping systems can be installed upon the needs for the fast curing of the concrete panels. Following the concrete cure, the table is tilted up to 80 degrees vertical position by hydraulic cylinders for the panels to be moved from the table safely without having damages.

TRIBAR MOULDS

Breakwater armor units are essential for protecting coastlines, harbors, and other marine structures from the forces of the sea. Tribar molds are an important component of these units, as they are used to create the unique triangular shape of the armor units. Tribar molds consist of 8 segments that form the the mold. These molds are used to cast the breakwater armor units out of concrete, which is a highly durable and wave-resistant material.

One of the key benefits of tribar molds is their versatility. They can be used to create breakwater armor units of different sizes depending on the specific application. Additionally, tribar molds can be customized to meet specific requirements and tribar molds are also highly efficient and cost-effective.

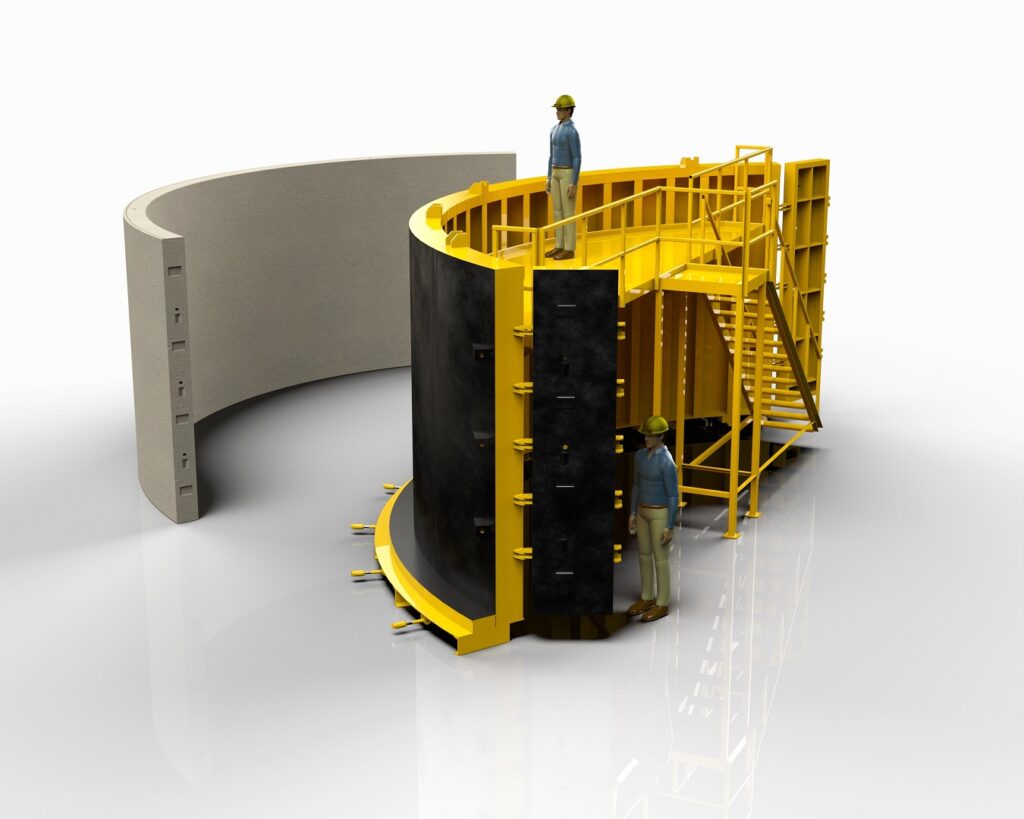

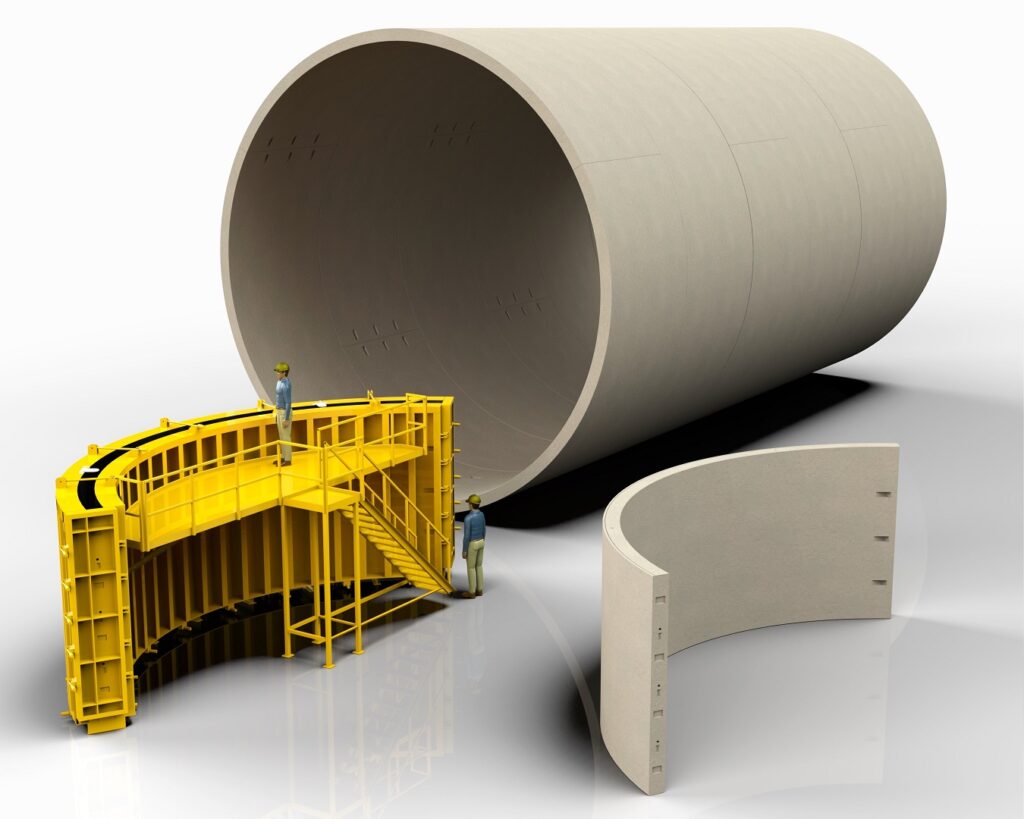

PRECAST TUNNEL SEGMENT MOULDS

Tunnel segment molds are an essential component of modern tunnel construction. These molds are used to create precast concrete segments that are pieced together to form the lining of a tunnel. The use of precast concrete segments has many advantages over traditional tunnel construction methods, including faster construction times, improved safety, and reduced environmental impact.

Tunnel segment molds are typically made of steel and can be custom-designed to fit the specifications of each individual project. The molds are used to create individual segments that are cast in a factory or onsite using a variety of high-strength concrete mixes. Once the segments are cast, they are typically transported to the construction site and pieced together using a specialized crane system. The segments are designed to interlock and form a strong, durable tunnel lining that is capable of withstanding the forces of the surrounding earth.

XBLOC PlUS® MOULDS

XBloc Plus is a leading brand of concrete armor units that are used for coastal and offshore protection design and developed by Delta Marine Consultants / BAM. These armor units are made using XBloc Plus molds which are available in a range of sizes and shapes to suit different coastal protection needs.

Xbloc® technology designed and developed by DMC (Delta Marine Consultants) / BAM

One of the key advantages of using XBloc Plus units is their ability to produce lightweight, interlocking structures that offer superior protection against waves, currents and erosion. In addition to their physical strength, XBloc Plus armor units are also designed to promote biodiversity by creating habitats for marine life. The development of the XBloc Plus Concrete units has been driven by a desire to create sustainable coastal protection solutions that reduce environmental impact. The molds are made from steel and are designed for easy assembly, transportation and storage.

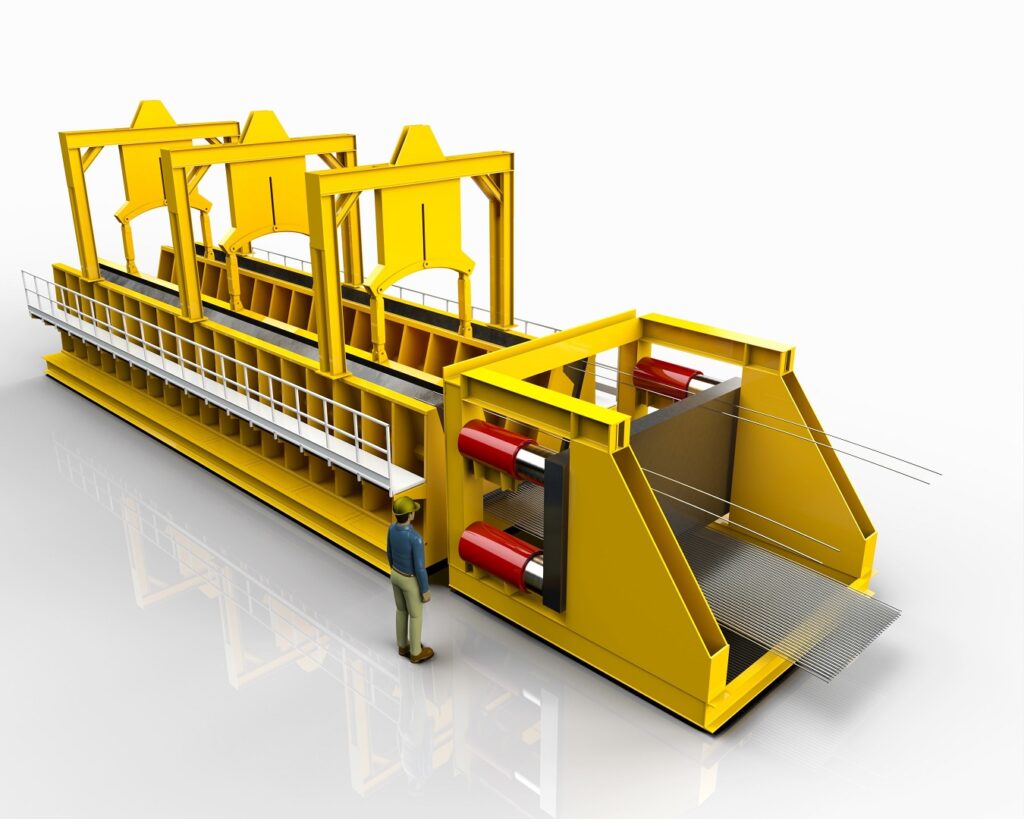

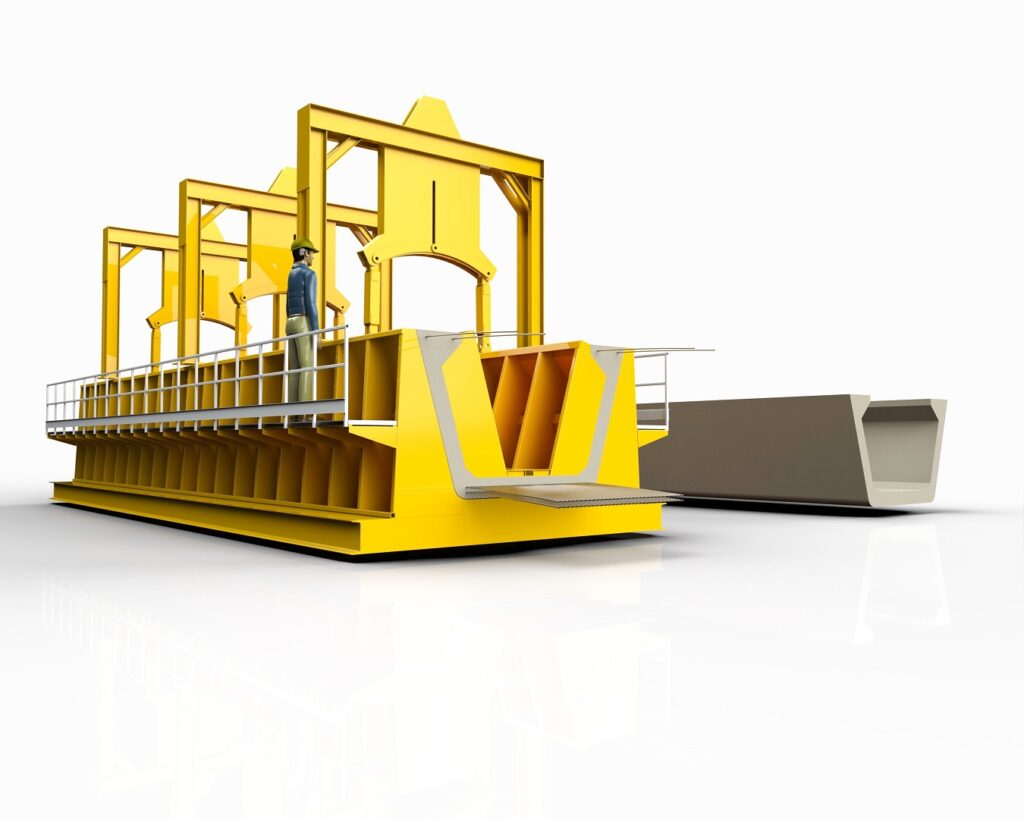

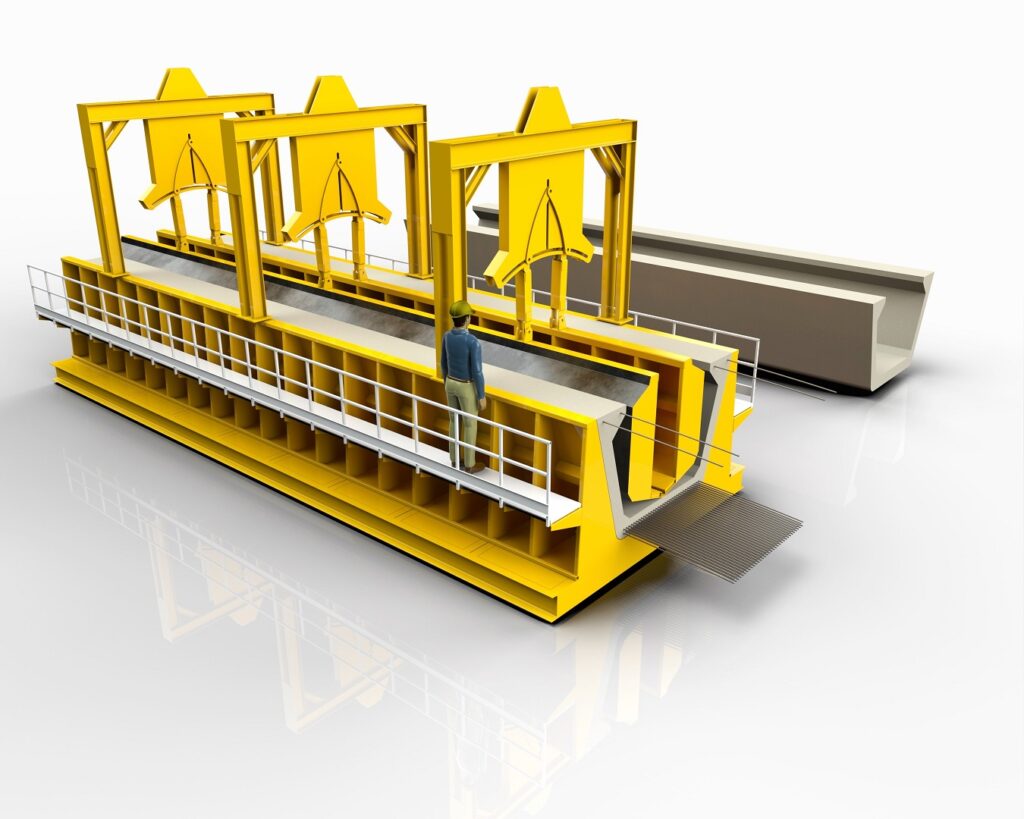

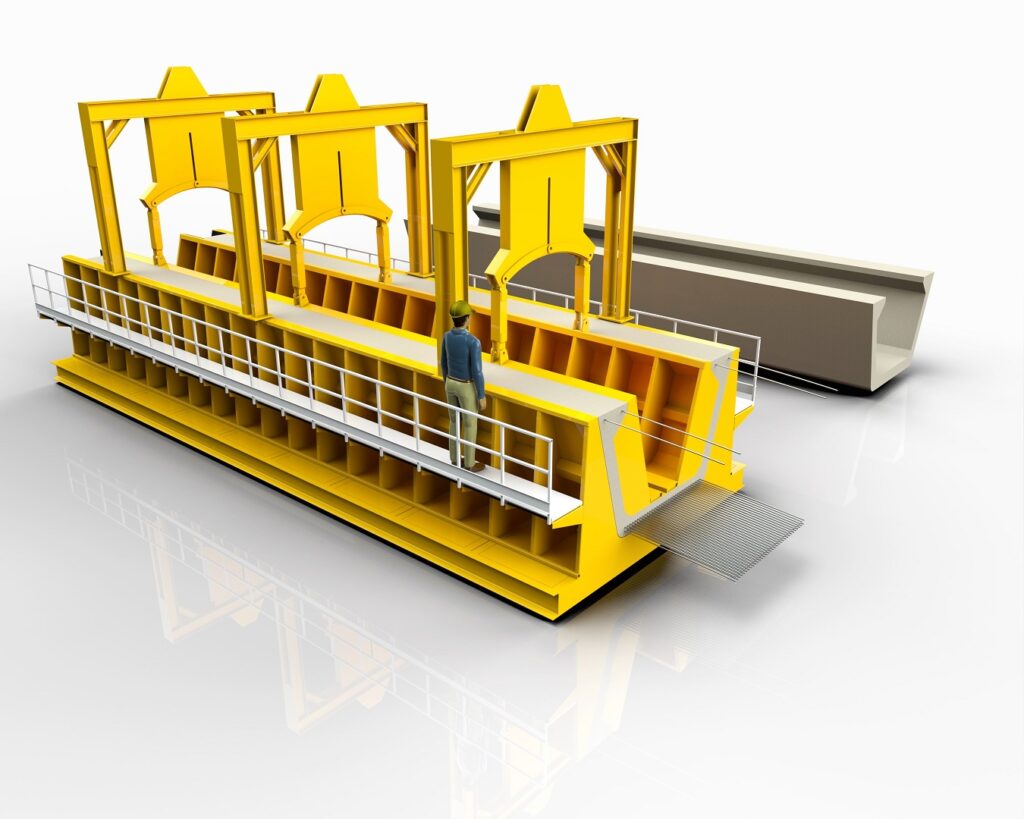

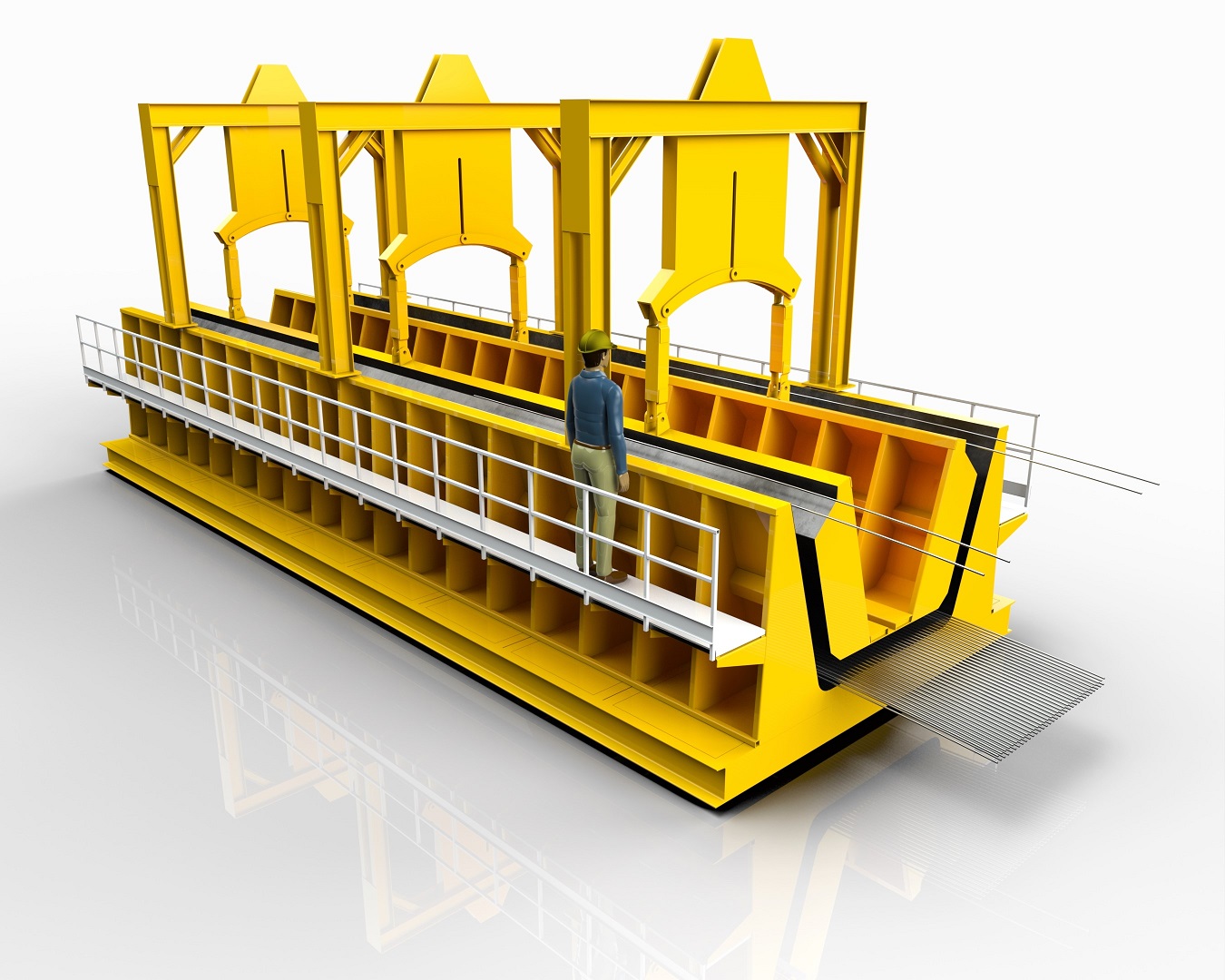

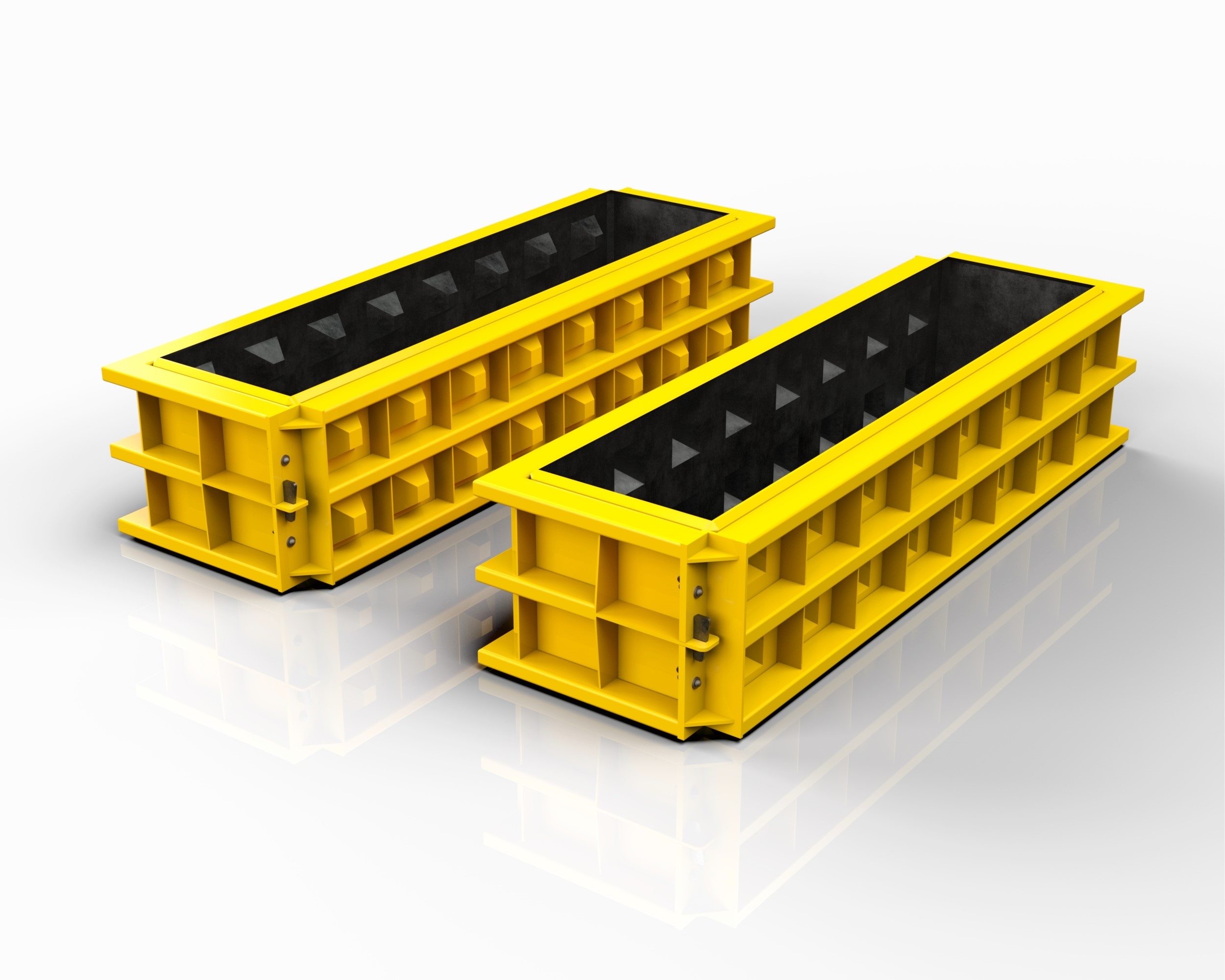

hydraulic prestressed girder MOULDS

Prestressed girder molds are an important tool in the construction industry for creating strong, durable, and reliable structural components. These molds are used to create prestressed girders, which are reinforced concrete beams that have been pre-tensioned or post-tensioned with steel strands or bars. The use of prestressed girders has become increasingly popular in recent years due to their ability to withstand heavy loads and long spans. These girders are commonly used in the construction of bridges, high-rise buildings, and other structures that require a high level of strength and durability.

To create prestressed girders, steel strands or bars are pre-tensioned or post-tensioned within a mold that is typically made of steel or fiberglass. These strands or bars are stretched to a predetermined tension level and then anchored to the mold. Once the concrete is poured into the mold, the tensioned strands or bars are released.

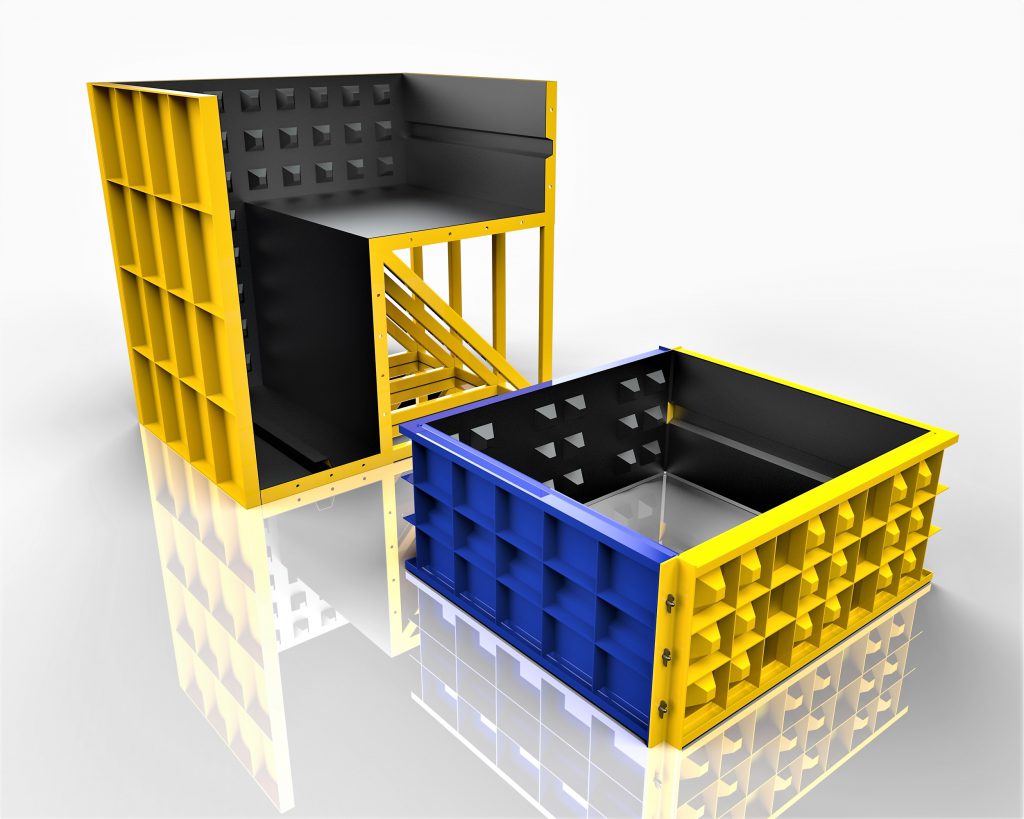

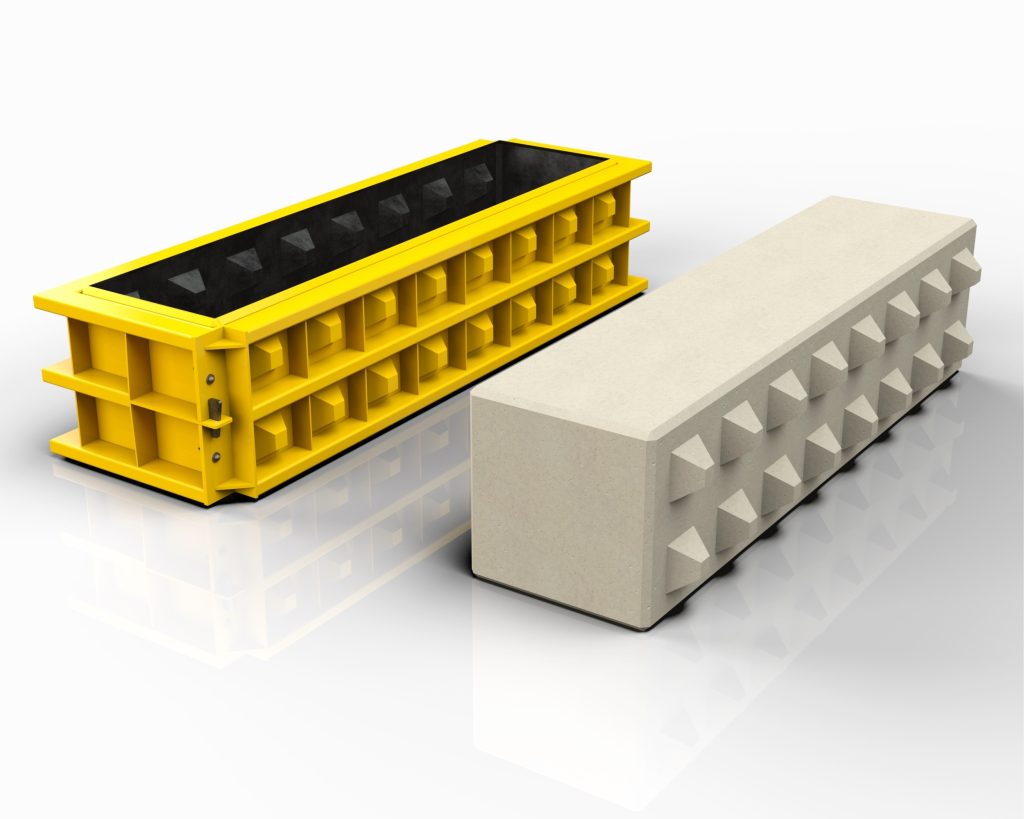

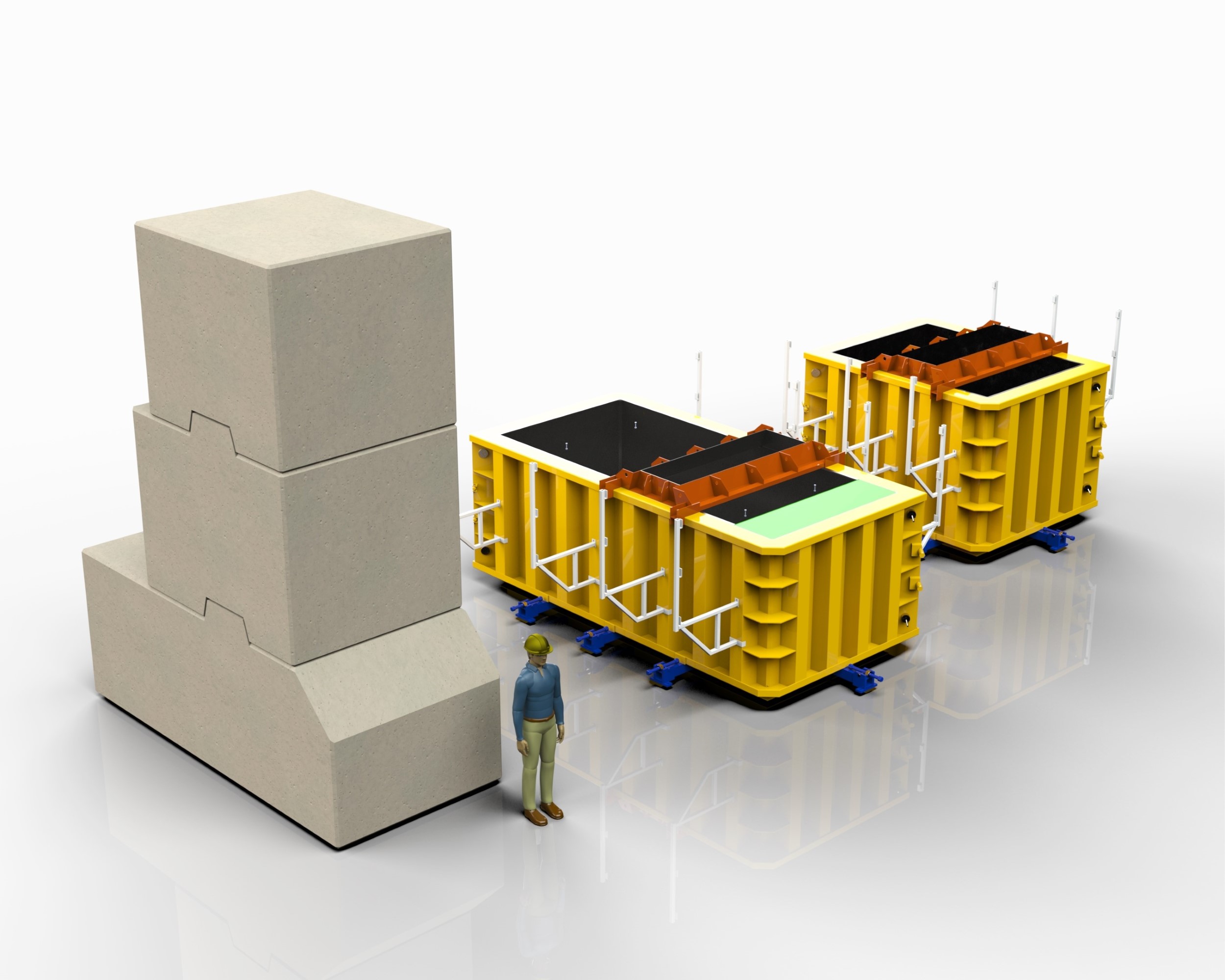

LEGO BLOCK MOULDS

Standard Rectangular shape lego Block moulds are made up of 2 elements. One having studs and other having recesses which makes it possible to have interlocking system when one block placed on an other. Depending upon our client's needs we produce Lego block moulds which has custom shape and dimensions.

Lego Block moulds are used in various ways and for various purposes such as material storage bays, Retaining walls, Flood Protection walls, Harbor Quay walls, etc.

Latest pROJECTS

Some of our latest project locations.

Malfa marina ACCROPODE™ project, Scalo Galera in Salina island - Sicily

Lustica Bay, ACCROPODE II™ Project, Montenegro

Rehabilitation of the Black Sea coast, Xbloc® Project, the Eforie area, Romania